Double Wall Corrugated Pipes Bend Manufacturer Stockist Exporter

- Home

- Double Wall Corrugated Pipes Bend

We are manufacturers, stockist and exporters of Double Wall Corrugated Pipes Bend in Mumbai.

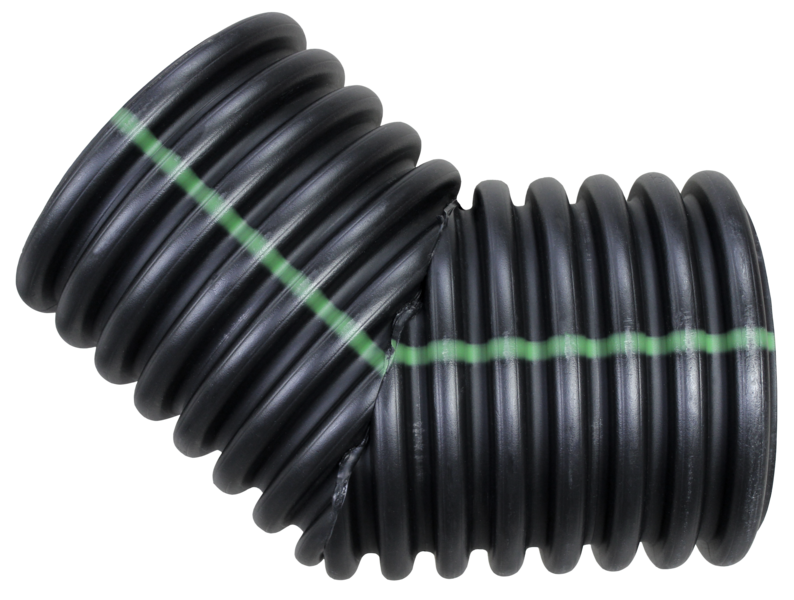

Synergy Engineering Solution is a prominent manufacturer, stockist, and exporter of high-quality Double Wall Corrugated Pipes Bend, widely used in underground cable ducts, sewage systems, stormwater drains, and infrastructure installations. A Double Wall Corrugated (DWC) Bend is a preformed curved fitting designed to enable directional changes in pipeline layouts while maintaining seamless flow, whether for cable routing or liquid discharge. These bends are engineered to handle heavy loads and environmental pressures while delivering long-lasting performance.

Made from premium-grade High-Density Polyethylene (HDPE), the DWC Pipes Bend features a corrugated external layer for strength and a smooth internal wall that allows for unobstructed flow and easy cable pulling. The bends are manufactured in various standard angles such as 30°, 45°, 60°, and 90°, and can be customized for project-specific routing requirements. Synergy offers sizes from OD 40 mm up to OD 500 mm, catering to both medium and large-scale installations.

The primary purpose of a DWC Pipes Bend is to provide a directional curve in a DWC pipeline system, often used in tight urban corridors, road crossings, telecom duct installations, and power cable routes. These bends eliminate the need for multiple fittings and joints, reducing the chances of leakage and cable stress. Their flexible yet robust design allows them to withstand soil load, traffic pressure, root intrusion, and corrosive environmental elements.

Synergy Engineering Solution proudly exports its DWC Bends to major global markets including Oman, Qatar, Saudi Arabia, UAE, Kuwait, Spain, Germany, the USA, Canada, and many parts of Africa. The products comply with stringent international standards such as IS 14930, EN 50086, and IEC 61386, making them suitable for global infrastructure projects. Their popularity is owed to Synergy's quality control processes, prompt deliveries, and superior customer support.

Our Other Valuable Products

These bends offer excellent mechanical properties such as high tensile strength, compression resistance, and temperature flexibility, making them ideal for underground as well as surface applications. The lightweight construction makes transportation and installation easier and faster compared to metal or concrete fittings. Furthermore, their ability to resist UV radiation, chemical exposure, and microbial growth enhances their lifespan, often exceeding 50 years in service.

Synergy ensures that each Double Wall Corrugated Pipe Bend undergoes rigorous testing for dimensional accuracy, load endurance, and material consistency. These fittings are easy to install using coupler-based jointing systems and provide a secure, leak-proof connection when used with rubber gaskets or clamps. Their flexibility and durability significantly reduce maintenance costs over time, making them a cost-effective solution for long-term infrastructure development.

Specification of Double Wall Corrugated Pipes Bend

| Property | Description |

|---|---|

| Product Name | Double Wall Corrugated Pipes Bend |

| Material | High-Density Polyethylene (HDPE) |

| Available Angles | 30°, 45°, 60°, 90° (Custom angles available) |

| Size Range | OD 40 mm to OD 500 mm |

| Wall Type | Outer Corrugated, Inner Smooth |

| Color | Black (Standard), Custom on request |

| Joint Type | Push-fit / Coupler-based |

| Application | Drainage, Sewer, Electrical, Telecom, Cable Routing |

| Compliance Standards | IS 14930, EN 50086, IEC 61386 |

Chemical Composition of Double Wall Corrugated Pipes Bend

| Component | Percentage (%) |

|---|---|

| Carbon (C) | 85–87 |

| Hydrogen (H) | 12–14 |

| UV/Antioxidant Additives | <2 |

Mechanical Properties of Double Wall Corrugated Pipes Bend

| Property | Value |

|---|---|

| Density | 0.941 – 0.965 g/cm³ |

| Tensile Strength | ≥ 26 MPa |

| Flexural Modulus | 800 – 1300 MPa |

| Temperature Resistance | -40°C to +80°C |

| Compression Strength | Excellent for underground applications |

| Impact Resistance | High |

| Service Life | 50+ years |

Used extensively in power grid projects, fiber-optic network deployments, municipal sewage systems, and industrial cable installations, these bends are indispensable wherever directional flow or cable redirection is required. With high performance and environmental sustainability, Synergy's DWC Bends are trusted worldwide for both government and private infrastructure projects.

Pipe Testing Methods

Pipe Applications

We supply Pipes Worldwide.

Exporting Steel Pipes & Tubes to over 60 countries including Afghanistan, Albania, Andorra, Angloa, Austria, Australia, Bahrain, Bangladesh, Bhutan, Brazil, Brunei, Belarus, Belgium, Bulgaria, Cambodia, China, Cyprus, Croatia, Czech Republic, Canada, Denmark, Estonia, Egypt, Finland, France, Germany, Greece, Georgia, Hungary, Iceland, Ireland, Italy, Indonesia, Iran, Iraq, Israel, Japan, Jordan, Kazakhstan, Kuwait, Kyrgyzstan, Lebanon, Latvia, Latin America, Liechtenstein, Lithuania, Luxembourg, Malta, Madagascar, Mexico, Moldova, Monaco, Malaysia, Maldives, Mongolia, Myanmar (Burma), Nepal, New Zealand, North Korea, Netherlands, Norway, Nigeria, Oman, Poland, Portugal, Pakistan, Palestine, Philippines, Qatar, Russia, Romania, Russia, San Marino, Serbia and Montenegro, Slovakia, Slovenia, Spain, Sweden, Switzerland, Saudi Arabia, Singapore, South Korea, South Africa, Sri Lanka, Sudan, Syria, Taiwan, Tanzania, Tajikistan, Thailand, Turkey, Turkmenistan, Ukraine, United Kingdom, United Arab Emirates (UAE), Uzbekistan, Venezuela, Vietnam, Yemen, etc.