UNS N06600 Inconel 600 ERW Pipes Manufacturer Stockist Exporter

- Home

- UNS N06600 Inconel 600 ERW Pipes

We are manufacturers, stockist and exporters of UNS N06600 Inconel 600 ERW Pipes in Mumbai.

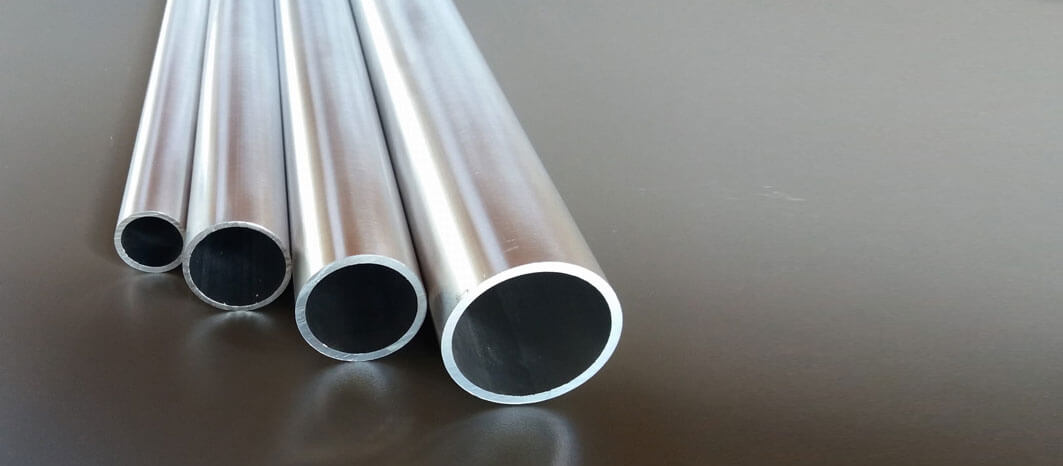

Synergy Engineering Solution is a renowned manufacturer, stockist, and exporter of UNS N06600 Inconel 600 ERW (Electric Resistance Welded) pipes. These pipes are made from Inconel 600, a nickel-chromium alloy known for its excellent resistance to high temperatures, oxidation, and corrosion. UNS N06600, also referred to as Inconel 600, is a versatile alloy, primarily composed of nickel (around 72%), chromium (14-17%), and iron (balance), with trace amounts of manganese, silicon, and carbon. It is specifically designed for applications that demand resistance to oxidation, carburization, and thermal-fatigue environments, making it ideal for industries such as chemical processing, aerospace, and heat exchangers.

At Synergy Engineering Solution, the manufacturing of UNS N06600 Inconel 600 ERW pipes is carried out under stringent quality controls to ensure that every pipe adheres to international standards. These pipes are produced through the Electric Resistance Welding process, which provides uniformity, strength, and precise dimensions. The ERW method allows for the creation of pipes with thinner walls compared to seamless pipes, offering a cost-effective alternative without sacrificing performance. The inherent strength of Inconel 600 ensures that these pipes maintain their structural integrity in high-temperature environments, making them suitable for use in applications that involve heat exchangers, furnace components, and nuclear reactors.

The company’s role as a stockist further enhances its ability to supply UNS N06600 Inconel 600 ERW pipes in various sizes and specifications. Synergy Engineering Solution is committed to keeping a large inventory of Inconel 600 pipes in stock, ready for immediate shipment, which helps ensure fast and efficient delivery times for clients in Oman, Qatar, Saudi Arabia, UAE, Kuwait, Spain, Germany, the USA, Canada, and many African countries. This comprehensive inventory allows the company to provide a wide range of pipe sizes, wall thicknesses, and lengths, catering to both standard and custom requirements for diverse industries across the globe.

As a trusted exporter, Synergy Engineering Solution serves multiple regions worldwide, providing Inconel 600 ERW pipes that meet the highest quality standards. The company has established a solid reputation for timely and reliable deliveries, offering pipes that are resistant to oxidation, carburization, and various forms of high-temperature corrosion. These properties are essential for industries operating under extreme conditions, such as power generation, chemical processing, and aerospace. Inconel 600’s excellent mechanical properties and resistance to various corrosive environments make these ERW pipes an ideal choice for applications like furnace applications, heat treating, and parts exposed to elevated temperatures and aggressive chemicals.

Our Other Valuable Products

With its robust network of suppliers and logistics partners, Synergy Engineering Solution can efficiently deliver UNS N06600 Inconel 600 ERW pipes across key regions such as the Middle East, Europe, North America, and Africa. The company’s commitment to excellence ensures that every pipe supplied is carefully inspected for quality, dimensional accuracy, and performance, making it a trusted source for critical applications that require long-lasting durability and resistance to severe operating conditions. Whether serving the energy sector in the UAE, the aerospace industry in Spain, or chemical refineries in Canada, Synergy Engineering Solution’s Inconel 600 pipes are essential components in various engineering applications worldwide.

Synergy Engineering Solution’s focus on customer satisfaction and technical expertise has earned it the loyalty of clients in regions such as Oman, Qatar, Saudi Arabia, the UAE, Kuwait, Spain, Germany, the USA, Canada, and many countries in Africa. By offering consistent and dependable products backed by exceptional customer service, Synergy Engineering Solution has become a preferred supplier of UNS N06600 Inconel 600 ERW pipes. Whether in high-temperature furnace operations, heat exchangers, or challenging chemical environments, these pipes continue to provide superior performance, ensuring long-term value and reliability in demanding industrial applications across the globe.

Chemical Properties of UNS N06600 Inconel 600 ERW Pipes

| Element | Composition (wt%) |

|---|---|

| Nickel (Ni) | 38.0 - 46.0 |

| Chromium (Cr) | 19.5 - 23.5 |

| Iron (Fe) | Balance |

| Molybdenum (Mo) | 2.5 - 3.5 |

| Copper (Cu) | 1.0 - 3.0 |

| Titanium (Ti) | 0.6 - 1.2 |

| Aluminum (Al) | 0.2 - 0.8 |

| Manganese (Mn) | 1.0 max |

| Silicon (Si) | 0.5 max |

| Carbon (C) | 0.05 max |

| Sulfur (S) | 0.02 max |

| Phosphorus (P) | 0.04 max |

Mechanical properties of UNS N06600 Inconel 600 ERW Pipes

| Property | Value |

|---|---|

| Tensile Strength | 620 MPa (90 ksi) |

| Yield Strength (0.2% Offset) | 240 MPa (35 ksi) |

| Elongation (in 2 inches or 50 mm) | 35% minimum |

| Hardness | 170 - 220 HB (Brinell Hardness) |

| Modulus of Elasticity | 200 GPa (29 × 10³ ksi) |

| Poisson's Ratio | 0.31 |

| Density | 8.44 g/cm³ (8440 kg/m³) |

| Fatigue Strength | 345 MPa (50 ksi) at 10⁶ cycles |

In order to alter the physical and mechanical characteristics of metal without altering its original shape and size, we offer a variety of heat treatment services, including hydrogen heat treatment, HIC testing, blasting and painting, cutting, arc welding, epoxy cutting, PMI testing, hydro testing, NACE testing, and SSC testing. Although heat treatment is frequently linked to a metal's increased strength, it can also be used to change specific manufacturability goals, such enhancing machinability, formability, ductility, etc. The metal and heavy manufacturing sectors use our services. Customers have expressed great pleasure with our services' precision, efficacy, cost, and prompt delivery.

Pipe Testing Methods

Pipe Applications

We supply Pipes Worldwide.

Exporting Steel Pipes & Tubes to over 60 countries including Afghanistan, Albania, Andorra, Angloa, Austria, Australia, Bahrain, Bangladesh, Bhutan, Brazil, Brunei, Belarus, Belgium, Bulgaria, Cambodia, China, Cyprus, Croatia, Czech Republic, Canada, Denmark, Estonia, Egypt, Finland, France, Germany, Greece, Georgia, Hungary, Iceland, Ireland, Italy, Indonesia, Iran, Iraq, Israel, Japan, Jordan, Kazakhstan, Kuwait, Kyrgyzstan, Lebanon, Latvia, Latin America, Liechtenstein, Lithuania, Luxembourg, Malta, Madagascar, Mexico, Moldova, Monaco, Malaysia, Maldives, Mongolia, Myanmar (Burma), Nepal, New Zealand, North Korea, Netherlands, Norway, Nigeria, Oman, Poland, Portugal, Pakistan, Palestine, Philippines, Qatar, Russia, Romania, Russia, San Marino, Serbia and Montenegro, Slovakia, Slovenia, Spain, Sweden, Switzerland, Saudi Arabia, Singapore, South Korea, South Africa, Sri Lanka, Sudan, Syria, Taiwan, Tanzania, Tajikistan, Thailand, Turkey, Turkmenistan, Ukraine, United Kingdom, United Arab Emirates (UAE), Uzbekistan, Venezuela, Vietnam, Yemen, etc.