UNS N04400 Monel 400 Tubes Manufacturer Stockist Exporter

- Home

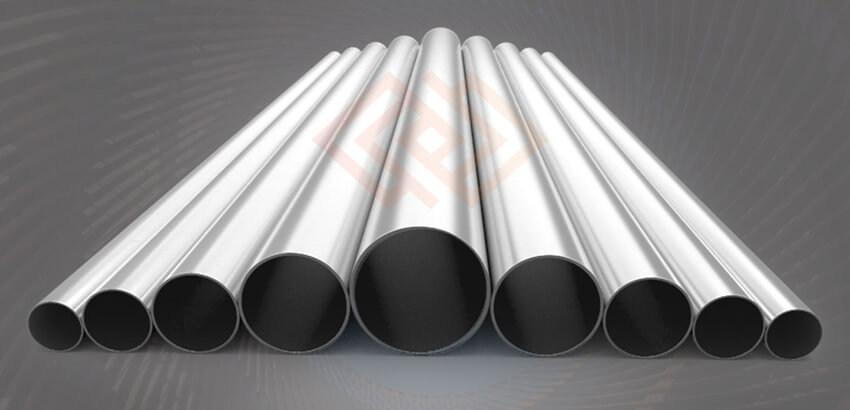

- UNS N04400 Monel 400 Tubes

We are manufacturers, stockist and exporters of UNS N04400 Monel 400 Tubes in Mumbai.

UNS N04400 Monel 400 is a high-performance alloy primarily composed of nickel (about 63%) and copper (about 30%), with smaller amounts of iron, manganese, carbon, and silicon. This alloy is renowned for its excellent resistance to a wide range of corrosive environments, especially in sea water and acidic conditions. As a result, Monel 400 is extensively used in marine engineering, chemical processing, and various industries where high strength and corrosion resistance are crucial. The alloy also maintains its mechanical properties at both low and high temperatures, making it a versatile choice for several demanding applications.

Synergy Engineering Solution is a leading manufacturer, stockist, and exporter of UNS N04400 Monel 400 tubes. The company has established itself as a reliable supplier of high-quality Monel 400 products, providing solutions to clients worldwide. With an extensive inventory, Synergy Engineering Solution offers Monel 400 tubes in various sizes, wall thicknesses, and lengths to meet diverse industrial needs. Their Monel 400 tubes are engineered to the highest standards, ensuring they perform effectively in challenging environments, including offshore, chemical plants, and marine sectors.

In addition to manufacturing Monel 400 tubes, Synergy Engineering Solution serves as a trusted stockist and exporter across multiple regions. Their global reach extends to key markets like Oman, Qatar, Saudi Arabia, the UAE, Kuwait, Spain, Germany, the USA, and Canada. The company is also deeply involved in supplying to various regions across Africa, ensuring that businesses worldwide have access to top-tier Monel 400 materials. Their extensive distribution network guarantees timely deliveries and ensures customers receive the necessary materials for their projects without unnecessary delays.

Synergy Engineering Solution’s Monel 400 tubes are highly regarded for their exceptional resistance to corrosion in both marine and industrial environments. The alloy’s ability to withstand seawater, sulfuric acid, hydrofluoric acid, and other corrosive agents makes it the material of choice for industries like shipbuilding, oil and gas, chemical processing, and power generation. Its superior mechanical properties, including high strength, ductility, and toughness, allow it to perform in demanding applications such as heat exchangers, valves, pumps, and pressure vessels.

Our Other Valuable Products

The company’s commitment to quality is evident in their stringent testing and inspection processes. Every batch of UNS N04400 Monel 400 tubes undergoes rigorous testing for mechanical properties, corrosion resistance, and dimensional accuracy to ensure they meet or exceed international standards. This commitment to quality and precision has earned Synergy Engineering Solution a strong reputation in the global market, making them a preferred choice for Monel 400 tubes.

With a customer-first approach, Synergy Engineering Solution prides itself on offering competitive prices, reliable delivery schedules, and superior customer service. Their expertise in Monel 400 and their experience in exporting to a wide range of countries make them a go-to provider for high-quality tubes, backed by a reputation for excellence in the industry. Whether for small-scale projects or large industrial applications, Synergy Engineering Solution is well-equipped to fulfill the diverse needs of their global client base.

Chemical Properties of UNS N04400 Monel 400 Tubes

| Element | Composition (%) |

|---|---|

| Nickel (Ni) | 63.0 – 70.0 |

| Copper (Cu) | 28.0 – 34.0 |

| Iron (Fe) | Max 2.5 |

| Manganese (Mn) | Max 2.0 |

| Carbon (C) | Max 0.03 |

| Silicon (Si) | Max 0.5 |

| Sulfur (S) | Max 0.024 |

| Phosphorus (P) | Max 0.015 |

Mechanical properties of UNS N04400 Monel 400 Tubes

| Property | Value |

|---|---|

| Tensile Strength | 70 – 100 ksi (485 – 690 MPa) |

| Yield Strength (0.2% offset) | 30 – 60 ksi (205 – 415 MPa) |

| Elongation | 35% (in 8 inches / 200 mm) |

| Hardness (Brinell) | 120 – 170 HB |

| Modulus of Elasticity | 200 x 10³ ksi (1380 x 10³ MPa) |

| Poisson's Ratio | 0.31 – 0.34 |

| Density | 8.80 g/cm³ (8800 kg/m³) |

In order to alter the physical and mechanical characteristics of metal without altering its original shape and size, we offer a variety of heat treatment services, including hydrogen heat treatment, HIC testing, blasting and painting, cutting, arc welding, epoxy cutting, PMI testing, hydro testing, NACE testing, and SSC testing. Although heat treatment is frequently linked to a metal's increased strength, it can also be used to change specific manufacturability goals, such enhancing machinability, formability, ductility, etc. The metal and heavy manufacturing sectors use our services. Customers have expressed great pleasure with our services' precision, efficacy, cost, and prompt delivery.

Pipe Testing Methods

Pipe Applications

We supply Pipes Worldwide.

Exporting Steel Pipes & Tubes to over 60 countries including Afghanistan, Albania, Andorra, Angloa, Austria, Australia, Bahrain, Bangladesh, Bhutan, Brazil, Brunei, Belarus, Belgium, Bulgaria, Cambodia, China, Cyprus, Croatia, Czech Republic, Canada, Denmark, Estonia, Egypt, Finland, France, Germany, Greece, Georgia, Hungary, Iceland, Ireland, Italy, Indonesia, Iran, Iraq, Israel, Japan, Jordan, Kazakhstan, Kuwait, Kyrgyzstan, Lebanon, Latvia, Latin America, Liechtenstein, Lithuania, Luxembourg, Malta, Madagascar, Mexico, Moldova, Monaco, Malaysia, Maldives, Mongolia, Myanmar (Burma), Nepal, New Zealand, North Korea, Netherlands, Norway, Nigeria, Oman, Poland, Portugal, Pakistan, Palestine, Philippines, Qatar, Russia, Romania, Russia, San Marino, Serbia and Montenegro, Slovakia, Slovenia, Spain, Sweden, Switzerland, Saudi Arabia, Singapore, South Korea, South Africa, Sri Lanka, Sudan, Syria, Taiwan, Tanzania, Tajikistan, Thailand, Turkey, Turkmenistan, Ukraine, United Kingdom, United Arab Emirates (UAE), Uzbekistan, Venezuela, Vietnam, Yemen, etc.