N-12 Dual Wall Pipe Manufacturer Stockist Exporter

- Home

- N-12 Dual Wall Pipe

We are manufacturers, stockist and exporters of N-12 Dual Wall Pipe in Mumbai.

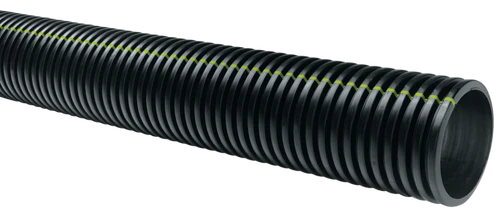

Synergy Engineering Solution is a distinguished manufacturer, stockist, and exporter of high-performance N-12 Dual Wall Pipes, designed to offer superior strength, hydraulic performance, and long-term durability in demanding drainage and stormwater management applications. Made from High-Density Polyethylene (HDPE), these pipes feature a smooth interior wall for high flow rates and a corrugated exterior wall for exceptional structural integrity. The N-12 designation refers to the pipe’s minimum pipe stiffness rating of 335 kPa (50 psi) as per ASTM D3212 and AASHTO M252/M294 specifications.

The N-12 Dual Wall Pipe is engineered to outperform traditional materials such as concrete and metal, especially in underground drainage, culverts, storm sewers, detention systems, and highway subdrainage applications. The smooth interior ensures minimal friction loss, enabling faster water flow, while the corrugated exterior provides high resistance to external loads and soil pressure. These pipes are lightweight and easy to handle, reducing installation costs and time, making them a preferred choice for both contractors and engineers globally.

Synergy manufactures these pipes using co-extrusion technology, ensuring a perfect bond between the inner and outer layers. The standard N-12 pipe meets or exceeds the performance requirements of AASHTO M294 Type S, and is available in a wide range of diameters from 100 mm to 1500 mm (4" to 60"), supplied in 6 or 12-meter lengths. Joint connections are made with bell-and-spigot systems featuring gasketed water-tight seals, ensuring leak-proof performance for gravity-flow and low-pressure applications.

As a comprehensive stockist, Synergy Engineering Solution maintains a large inventory of N-12 pipes and accessories including fittings, couplers, tees, elbows, reducers, and manholes. The company serves global infrastructure projects across Oman, Qatar, Saudi Arabia, UAE, Kuwait, Spain, Germany, the USA, Canada, and Africa, with full support for international certifications, third-party inspections, custom labeling, and material test reports (MTRs).

Our Other Valuable Products

The pipes are manufactured from virgin HDPE resins, offering excellent resistance to abrasion, chemicals, biological growth, and corrosion. Unlike traditional piping systems, N-12 pipes do not require protective coatings and can withstand aggressive environments including industrial effluents, saline groundwater, and acidic soils. Their high impact strength ensures they do not crack under heavy construction loads or during transportation and installation.

These N-12 pipes are also environmentally sustainable, 100% recyclable, and require minimal maintenance over their lifecycle. Their high flow capacity and low Manning's roughness coefficient (as low as 0.012) allow for downsized designs and cost-efficient system installations. Whether used in municipal drainage, agricultural irrigation, highway runoff systems, or mining discharge networks, N-12 pipes provide a durable and cost-effective alternative to concrete or steel.

Specification of N-12 Dual Wall Pipe

| Property | Description |

|---|---|

| Product Name | N-12 Dual Wall Pipe |

| Diameter Range | 100 mm to 1500 mm (4" to 60") |

| Standard Length | 6 meters, 12 meters |

| Wall Construction | Smooth Inner Wall, Corrugated Outer Wall |

| Material | High-Density Polyethylene (HDPE) |

| Standards | AASHTO M252/M294 Type S, ASTM D3212, ASTM F2306 |

| Jointing Method | Bell-and-Spigot with Gasketed Seal |

| Manning's Coefficient | 0.012 |

| Applications | Drainage, Culverts, Highway Runoff, Agricultural and Stormwater |

Chemical Composition of N-12 Dual Wall Pipe

| Component | Percentage (%) |

|---|---|

| Carbon (C) | ~85 – 87 |

| Hydrogen (H) | ~12 – 14 |

| Additives | <1 (UV stabilizers, antioxidants, black pigment) |

Mechanical Properties of N-12 Dual Wall Pipe

| Property | Value |

|---|---|

| Density | 0.941 – 0.965 g/cm³ |

| Pipe Stiffness | ≥ 335 kPa (50 psi) |

| Tensile Strength | ≥ 26 MPa |

| Flexural Modulus | 800 – 1200 MPa |

| Impact Resistance | High |

| Crush Resistance | Excellent |

| Operating Temperature | -40°C to +80°C |

| UV Resistance | Excellent (Carbon Black Stabilized) |

| Manning’s n Value | 0.012 |

| Service Life | 75 – 100 years |

Synergy provides technical consulting, CAD support, and customized supply chain solutions to meet diverse project timelines and specifications. The company's dedication to quality control, engineering excellence, and customer satisfaction has made it a global leader in the supply of N-12 Dual Wall Pipes for modern infrastructure development.

Pipe Testing Methods

Pipe Applications

We supply Pipes Worldwide.

Exporting Steel Pipes & Tubes to over 60 countries including Afghanistan, Albania, Andorra, Angloa, Austria, Australia, Bahrain, Bangladesh, Bhutan, Brazil, Brunei, Belarus, Belgium, Bulgaria, Cambodia, China, Cyprus, Croatia, Czech Republic, Canada, Denmark, Estonia, Egypt, Finland, France, Germany, Greece, Georgia, Hungary, Iceland, Ireland, Italy, Indonesia, Iran, Iraq, Israel, Japan, Jordan, Kazakhstan, Kuwait, Kyrgyzstan, Lebanon, Latvia, Latin America, Liechtenstein, Lithuania, Luxembourg, Malta, Madagascar, Mexico, Moldova, Monaco, Malaysia, Maldives, Mongolia, Myanmar (Burma), Nepal, New Zealand, North Korea, Netherlands, Norway, Nigeria, Oman, Poland, Portugal, Pakistan, Palestine, Philippines, Qatar, Russia, Romania, Russia, San Marino, Serbia and Montenegro, Slovakia, Slovenia, Spain, Sweden, Switzerland, Saudi Arabia, Singapore, South Korea, South Africa, Sri Lanka, Sudan, Syria, Taiwan, Tanzania, Tajikistan, Thailand, Turkey, Turkmenistan, Ukraine, United Kingdom, United Arab Emirates (UAE), Uzbekistan, Venezuela, Vietnam, Yemen, etc.