UNS N02200 Nickel Alloy 200 Spectacle Flanges Manufacturer Stockist Exporter

- Home

- UNS N02200 Nickel Alloy 200 Spectacle Flanges

We are manufacturers, stockist and exporters of UNS N02200 Nickel Alloy 200 Spectacle Flanges in Mumbai.

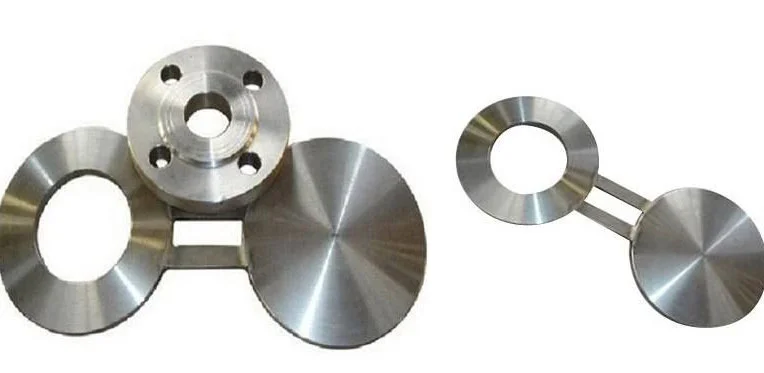

UNS N02200, commonly known as Nickel Alloy 200, is a commercially pure nickel-based alloy known for its excellent corrosion resistance in a variety of media, high ductility, good thermal conductivity, and stability over a broad temperature range. Because of its high purity and favorable properties, it is often used in chemical processing, marine, oil & gas, and other aggressive environments. The “spectacle” or “spectacle blind” flange is a special flange design having two discs (one blank and one open) joined by a small web — used to blind or bypass lines without disassembling pipework. When manufactured in Alloy 200, these spectacle flanges combine the mechanical utility with corrosion resistance and temperature stability inherent in UNS N02200.

As a reputed manufacturer, stockist, and exporter, Synergy Engineering Solution (sometimes trading under “Synergy Tubes / Synergy Engineering Solutions”) produces spectacle flanges from Nickel 200 in a range of sizes, pressure classes, and face types to meet international standards. According to their site, they provide a wide range of flanges, are an established manufacturer, stockist, and exporter of flanges. Their production approach would typically involve forging, machining, heat treatment, and finishing, followed by rigorous quality checks (such as dimensional inspection, hardness test, non-destructive testing, and material test certificates) to comply with standards like ASTM/ASME SB564 (for nickel flanges) or equivalent. In many cases, spectacle flanges in Nickel 200 must also pass intergranular corrosion tests, chemical analysis, and other material-specific checks to ensure reliability in aggressive service.

As a stockist, Synergy Engineering maintains inventories of Nickel 200 spectacle flanges and associated flange types (blind, lap joint, weld neck, slip-on, etc.) in various classes and dimensions. This allows them to provide faster lead times to clients by having ready stock rather than always manufacturing to order. Their website claims that they export “worldwide” including the Middle East, Africa, and beyond. Because spectacle flanges are often needed for pipeline isolation or maintenance in critical systems, having authorized stock and the ability to supply globally is a competitive advantage for Synergy in responding to urgent project demands.

Synergy’s export footprint spans across the Gulf region and global markets. Based in the UAE and with representation in Saudi Arabia, they are well-positioned to serve Oman, Qatar, UAE, and Kuwait markets. yond the Middle East, they can export to European markets like Spain and Germany, and to North America (USA, Canada), as well as across Africa. Their claim to “exports worldwide” suggests capabilities in global logistics, customs, and sourcing to support clients in diverse regions. For clients in these markets, Synergy can likely handle international shipping, packing, certifications (mill test certificates, third-party inspection), and compliance with regional regulations.

Types Of Flanges manufacturer

Nickel 200 spectacle flanges are particularly useful in chemical processing, petrochemical, offshore oil and gas, desalination, power, and marine applications. Their main advantage lies in the ability to isolate or bypass lines while preserving corrosion resistance and mechanical integrity in harsh environments. Compared to spectacle flanges in more common materials (e.g. carbon steel or stainless steel), the Nickel 200 variants offer superior resistance in acids, alkalis, and chloride-containing solutions. Many projects in the Gulf, North Africa, and beyond demand high-spec materials, making these flanges well suited for infrastructure in those regions.

With a robust global logistics network, Synergy Engineering Solutions is capable of delivering these high-performance flanges efficiently to any region worldwide. Their dedication to quality, timely delivery, and customer satisfaction positions them as a leading supplier of Inconel 800 Lapped Joint Flanges for industries that demand superior corrosion resistance, high temperature strength, and operational reliability.

Specification of Nickel Alloy 200 Spectacle Flanges

| Grade | Nickel 200 |

|---|---|

| UNS Number | N02200 |

| Standard | ASTM B564 / ASME SB564 |

| Size Range | 1/2” to 48” (DN15 to DN1200) |

| Pressure Class | 150#, 300#, 600#, 900#, 1500#, 2500# |

| Type | Spectacle Blind Flanges / Spacer & Spade |

| Face Type | Raised Face (RF), Flat Face (FF), Ring Type Joint (RTJ) |

Chemical Composition of Nickel Alloy 200

| Element | Percentage (%) |

|---|---|

| Nickel (Ni) | Min 99.0 |

| Copper (Cu) | Max 0.25 |

| Iron (Fe) | Max 0.40 |

| Manganese (Mn) | Max 0.35 |

| Carbon (C) | Max 0.15 |

| Silicon (Si) | Max 0.35 |

| Sulfur (S) | Max 0.01 |

Mechanical Properties of Nickel 200

| Property | Value |

|---|---|

| Tensile Strength | ≥ 415 MPa |

| Yield Strength (0.2% Offset) | ≥ 148 MPa |

| Elongation | ≥ 40% |

| Hardness | ≤ 70 HRB |

Equivalent Grades of Nickel 200

| Standard | Equivalent Grade |

|---|---|

| EN | Ni 99.2 |

| BS | NA 11 |

| JIS | NW 2200 |

| GOST | НП2 |

| DIN | 2.4066 / 2.4068 |

Frequently Asked Questions (FAQ)

Q: What are UNS N02200 Nickel Alloy 200 Spectacle Flanges used for?

They are used in pipelines to isolate or bypass flow during maintenance operations. Common industries include chemical, marine, oil & gas, and power generation.

Q: What standards govern Nickel 200 Spectacle Flanges?

These flanges conform to ASTM B564 and ASME SB564 standards, ensuring superior dimensional accuracy and material consistency.

Q: Why choose Nickel 200 over stainless steel for spectacle flanges?

Nickel 200 provides better resistance to caustic alkalis and chloride ion stress-corrosion cracking than stainless steels, making it ideal for chemical processing environments.

Q: Which countries does Synergy Engineering export to?

Synergy exports Nickel 200 Spectacle Flanges to Oman, Qatar, Saudi Arabia, UAE, Kuwait, Spain, Germany, the USA, Canada, Africa, and many other countries.

Q: What testing is performed on these flanges?

Each flange undergoes material testing, hardness checks, NDT, PMI, and third-party inspection to ensure international quality compliance.

In order to alter the physical and mechanical characteristics of metal without altering its original shape and size, we offer a variety of heat treatment services, including hydrogen heat treatment, HIC testing, blasting and painting, cutting, arc welding, epoxy cutting, PMI testing, hydro testing, NACE testing, and SSC testing. Although heat treatment is frequently linked to a metal's increased strength, it can also be used to change specific manufacturability goals, such enhancing machinability, formability, ductility, etc. The metal and heavy manufacturing sectors use our services. Customers have expressed great pleasure with our services' precision, efficacy, cost, and prompt delivery.

Flanges Testing Methods

Flanges Applications

We supply Pipes Worldwide.

Exporting Steel Pipes & Tubes to over 60 countries including Afghanistan, Albania, Andorra, Angloa, Austria, Australia, Bahrain, Bangladesh, Bhutan, Brazil, Brunei, Belarus, Belgium, Bulgaria, Cambodia, China, Cyprus, Croatia, Czech Republic, Canada, Denmark, Estonia, Egypt, Finland, France, Germany, Greece, Georgia, Hungary, Iceland, Ireland, Italy, Indonesia, Iran, Iraq, Israel, Japan, Jordan, Kazakhstan, Kuwait, Kyrgyzstan, Lebanon, Latvia, Latin America, Liechtenstein, Lithuania, Luxembourg, Malta, Madagascar, Mexico, Moldova, Monaco, Malaysia, Maldives, Mongolia, Myanmar (Burma), Nepal, New Zealand, North Korea, Netherlands, Norway, Nigeria, Oman, Poland, Portugal, Pakistan, Palestine, Philippines, Qatar, Russia, Romania, Russia, San Marino, Serbia and Montenegro, Slovakia, Slovenia, Spain, Sweden, Switzerland, Saudi Arabia, Singapore, South Korea, South Africa, Sri Lanka, Sudan, Syria, Taiwan, Tanzania, Tajikistan, Thailand, Turkey, Turkmenistan, Ukraine, United Kingdom, United Arab Emirates (UAE), Uzbekistan, Venezuela, Vietnam, Yemen, etc.