UNS N02201 Nickel Alloy 201 Blind Blrf Flanges Manufacturer Stockist Exporter

- Home

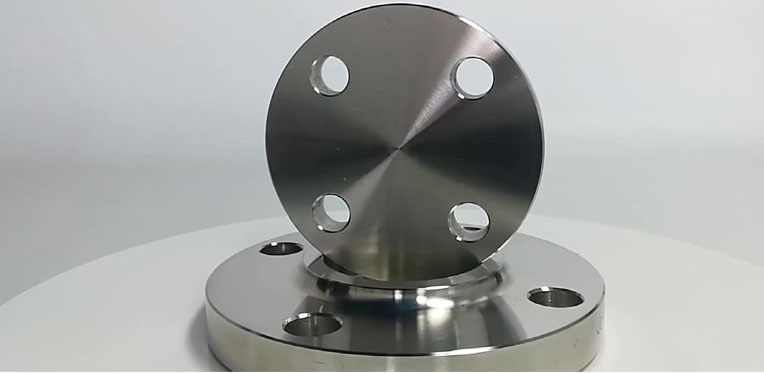

- UNS N02201 Nickel Alloy 201 Blind Blrf Flanges

We are manufacturers, stockist and exporters of UNS N02201 Nickel Alloy 201 Blind Blrf Flanges in Mumbai.

UNS N02201 Nickel Alloy 201 is a low-carbon variant of commercially pure wrought nickel (Nickel 200), specifically developed to resist graphitization and maintain ductility in high-temperature environments. It is widely recognized for its excellent resistance to corrosive chemicals, especially in reducing environments such as caustic alkalis and certain acids. Due to its low carbon content (0.02% max), Nickel 201 is highly suitable for applications involving temperatures above 600°F (315°C), where Nickel 200 may be susceptible to embrittlement. This makes UNS N02201 Nickel Alloy 201 a preferred material in industries like chemical processing, petrochemicals, food handling, electronics, and synthetic fiber manufacturing.

Synergy Engineering Solution is a leading manufacturer, stockist, and exporter of UNS N02201 Nickel Alloy 201 products, including sheets, plates, flanges, pipes, and fittings. The company adheres to international standards such as ASTM B160, B162, B366, and ASME specifications to ensure high performance and reliability. Their advanced manufacturing facilities are equipped with the latest technology for heat treatment, forming, and testing, enabling them to produce both standard and customized solutions tailored to specific project requirements.

Synergy Engineering Solution exports Nickel Alloy 201 to several international markets, including Oman, Qatar, Saudi Arabia, UAE, Kuwait, Spain, Germany, the USA, Canada, and various regions in Africa and worldwide. The demand for this alloy in these regions is driven by its exceptional corrosion resistance, high thermal and electrical conductivity, and stability under extreme temperatures. Nickel 201 is commonly used in pressure vessels, heat exchangers, chemical reactors, and marine components, where reliability and resistance to corrosive media are critical.

One of the key advantages of UNS N02201 is its magnetic and mechanical stability, especially at low temperatures, which makes it suitable for cryogenic systems and high-purity chemical processing equipment. The alloy also exhibits excellent weldability and formability, allowing for ease of fabrication and integration into complex industrial systems. Its low gas content and resistance to embrittlement make it ideal for high-performance applications where purity and structural integrity are essential.

Types Of Flanges manufacturer

Synergy Engineering Solution distinguishes itself through a strong commitment to quality, timely delivery, and customer satisfaction. All Nickel Alloy 201 products undergo rigorous inspection and testing, including PMI (Positive Material Identification), ultrasonic testing, and third-party certification. The company provides full material traceability and documentation, meeting the strictest compliance requirements for international procurement and engineering projects.

UNS N02201 Nickel Alloy 201 supplied by Synergy Engineering Solution is a high-performance material known for its durability, corrosion resistance, and reliability in high-temperature and chemically aggressive environments. With a solid global supply network and engineering excellence, Synergy is a trusted partner for industries seeking dependable nickel alloy solutions worldwide.

Specifications of UNS N02201 Nickel Alloy 201 Blind Blrf Flanges

| Specification Category | Details |

|---|---|

| Material Grade | UNS N02200 / Nickel Alloy 200 |

| Flange Type | Blind Raised Face (BLRF) Flange |

| Manufacturing Standard | ASTM B564 / ASME SB564 |

| Dimensions Standard | ASME B16.5, B16.47 Series A & B, MSS SP-44 |

| Size Range | ½” to 48” (DN15 to DN1200) |

| Pressure Ratings | Class 150, 300, 600, 900, 1500, 2500 / PN6 to PN64 |

| Face Type | Raised Face (RF), Flat Face (FF), Ring Type Joint (RTJ) |

| Temperature Range | -196°C to +315°C (-320°F to +600°F) |

| Corrosion Resistance | Excellent resistance to alkalis, neutral and alkaline salts, and dry gases |

| Applications | Chemical Processing, Electronics, Food Processing, Marine, Petrochemicals |

| Coating Options | Anti-rust oil, Black Paint, Zinc Plated, or customized as per request |

| Inspection & Testing | PMI, Ultrasonic Testing, Hydro Testing, EN 10204 3.1 / 3.2 Certification |

Chemical Properties of UNS N02201 Nickel Alloy 201 Blind Blrf Flanges

| Element | Composition (% by weight) |

|---|---|

| Nickel (Ni) | 99.0 min |

| Copper (Cu) | 0.25 max |

| Iron (Fe) | 0.40 max |

| Manganese (Mn) | 0.35 max |

| Silicon (Si) | 0.35 max |

| Carbon (C) | 0.15 max |

| Sulfur (S) | 0.01 max |

Mechanical properties of UNS N02201 Nickel Alloy 201 Blind Blrf Flanges

| Property | Value |

|---|---|

| Tensile Strength | 55,000 psi (380 MPa) minimum |

| Yield Strength (0.2%) | 11,000 psi (76 MPa) minimum |

| Elongation | 40% minimum |

| Hardness (Brinell) | 110 HB max |

| Modulus of Elasticity | 207 GPa (30 x 10³ ksi) |

| Melting Point | 1435–1446°C (2615–2635°F) |

| Impact Resistance | Excellent, maintains ductility at low temperatures |

| Density | 8.89 g/cm³ |

In order to alter the physical and mechanical characteristics of metal without altering its original shape and size, we offer a variety of heat treatment services, including hydrogen heat treatment, HIC testing, blasting and painting, cutting, arc welding, epoxy cutting, PMI testing, hydro testing, NACE testing, and SSC testing. Although heat treatment is frequently linked to a metal's increased strength, it can also be used to change specific manufacturability goals, such enhancing machinability, formability, ductility, etc. The metal and heavy manufacturing sectors use our services. Customers have expressed great pleasure with our services' precision, efficacy, cost, and prompt delivery.

Flanges Testing Methods

Flanges Applications

We supply Pipes Worldwide.

Exporting Steel Pipes & Tubes to over 60 countries including Afghanistan, Albania, Andorra, Angloa, Austria, Australia, Bahrain, Bangladesh, Bhutan, Brazil, Brunei, Belarus, Belgium, Bulgaria, Cambodia, China, Cyprus, Croatia, Czech Republic, Canada, Denmark, Estonia, Egypt, Finland, France, Germany, Greece, Georgia, Hungary, Iceland, Ireland, Italy, Indonesia, Iran, Iraq, Israel, Japan, Jordan, Kazakhstan, Kuwait, Kyrgyzstan, Lebanon, Latvia, Latin America, Liechtenstein, Lithuania, Luxembourg, Malta, Madagascar, Mexico, Moldova, Monaco, Malaysia, Maldives, Mongolia, Myanmar (Burma), Nepal, New Zealand, North Korea, Netherlands, Norway, Nigeria, Oman, Poland, Portugal, Pakistan, Palestine, Philippines, Qatar, Russia, Romania, Russia, San Marino, Serbia and Montenegro, Slovakia, Slovenia, Spain, Sweden, Switzerland, Saudi Arabia, Singapore, South Korea, South Africa, Sri Lanka, Sudan, Syria, Taiwan, Tanzania, Tajikistan, Thailand, Turkey, Turkmenistan, Ukraine, United Kingdom, United Arab Emirates (UAE), Uzbekistan, Venezuela, Vietnam, Yemen, etc.