UNS N05500 Monel K500 Lapped Joint Flanges Manufacturer Stockist Exporter

- Home

- UNS N05500 Monel K500 Lapped Joint Flanges

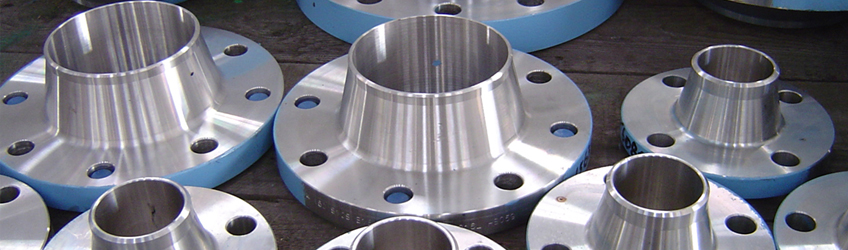

We are manufacturers, stockist and exporters of UNS N05500 Monel K500 Lapped Joint Flanges in Mumbai.

Monel K-500 (UNS N05500) is a precipitation-hardening nickel-copper alloy, combining the high corrosion resistance of Monel 400 with increased strength and hardness achieved via heat treatment (aging). The alloy contains aluminum and titanium as alloying elements, which enable precipitation of intermetallic phases during aging, giving it much higher strength levels than standard Monel 400 while retaining excellent corrosion resistance. Because of this combination of strength and corrosion performance, Monel K-500 is favored in highly demanding applications such as marine hardware, high-performance pump and valve components, aerospace components, and specialized chemical systems.

Synergy Engineering Solution, as a manufacturer, would procure high-integrity alloys of UNS N05500 and process them through controlled forging, solution heat-treatment, aging (to develop full strength), and precision machining to produce lapped joint flanges that meet strict dimensional and metallurgical standards. The production workflow must ensure that the precipitation-hardening process is carefully managed to produce consistent mechanical properties and avoid over-aging or brittle phases. Quality assurance would typically include chemical analysis, mechanical testing (tensile, hardness), and non-destructive examination where needed.

In its capacity as a stockist, Synergy would maintain inventories of commonly required sizes, pressure classes, and flange types (RF, FF, RTJ) in Monel K-500 lapped joint flanges. Stocking such a specialized alloy helps reduce lead times for clients who require small-lot or emergency orders, and builds confidence among projects that might otherwise see delays in sourcing a less commonly stocked superalloy. As an exporter, Synergy would manage packaging, documentation (such as material test certificates, heat-treatment records, certificates of origin), inspection, and logistics to deliver Monel K-500 flanges reliably into Oman, Qatar, Saudi Arabia, UAE, Kuwait, Spain, Germany, USA, Canada, and across Africa.

Lapped joint flanges made from Monel K-500 offer installation and alignment flexibility via the loose lap backing ring. This allows rotation or minor repositioning of the flange without inducing stress on the pipe run or disturbing fit-up, which is especially helpful in piping systems with tight geometry or complex skid layouts. When combined with Monel K-500’s enhanced mechanical strength and corrosion resistance, these flanges are particularly suited for high-stress, high-demand environments such as subsea hardware, marine systems, or high-pressure chemical loops where both strength and corrosion durability are required.

Types Of Flanges manufacturer

Synergy’s presence across the Middle East enables local access to inventory in strategic markets like Oman, Qatar, Saudi Arabia, UAE, and Kuwait, helping reduce transport times and cost for customers in those regions. In European markets (Spain, Germany) and North America (USA, Canada), Synergy competes as a niche, high-quality supplier of specialty alloys, emphasizing full documentation, traceability, and reliable export handling. In Africa and globally, Synergy aims to fill supply gaps in difficult-to-supply alloys such as Monel K-500. The company would support clients with technical advice on selecting the right flange dimensions, aging schedules, and material certification to ensure performance over service life.

Monel K-500 lapped joint flanges supplied by Synergy would find use in high-performance rotating equipment, marine and subsea systems, high-pressure chemical loops, and any corrosive environment where strength, fatigue resistance, and corrosion resistance must coexist. Synergy’s role is not merely as a vendor, but as a technical partner — helping customers choose flange types, material finishes, bolt/gasket compatibility, and aligning delivery schedules to project timelines. By combining in-house manufacturing, ready stock, and global export capability, Synergy Engineering Solution positions itself as a reliable global supplier of Monel K-500 lapped joint flanges.

Specifications

| Attribute | Details |

|---|---|

| Material Grade | UNS N05500 / Monel K-500 |

| Standards | ASME B16.5, ANSI B16.47, MSS SP-44, EN/DIN equivalents on request |

| Style | Lapped Joint Flanges (Lap Flange + Lapped Ring) |

| Size Range | ½" to 48" (DN15 to DN1200) — custom sizes available |

| Pressure Classes | 150#, 300#, 600#, 900#, 1500#, 2500# |

| Facing Options | RF (Raised Face), FF (Flat Face), RTJ (Ring Type Joint) |

| Documentation | Material Test Reports (MTR), Heat Treatment Records, Third-Party Inspection (optional) |

Chemical Composition (typical / ranges)

Note: percentages are typical ranges from common industry datasheets; final composition is supplied with MTRs.

| Element | Typical Range / Value (wt%) |

|---|---|

| Nickel (Ni) | 63.0 – 70.0 (balance) |

| Copper (Cu) | 27.0 – 33.0 |

| Aluminum (Al) | 2.30 – 3.15 |

| Titanium (Ti) | 0.35 – 0.85 |

| Iron (Fe) | ≤ 2.0 |

| Manganese (Mn) | ≤ 1.5 |

| Silicon (Si) | ≤ 0.50 |

| Carbon (C) | ≤ 0.18 – 0.25 (max, depending on spec) |

| Sulfur (S) | ≤ 0.01 (typical) |

Mechanical Properties (typical)

Properties vary significantly with heat-treatment (annealed vs aged). Values below show common ranges for annealed and aged (precipitation-hardened) conditions — confirm required condition and MTRs at order.

| Condition | Tensile Strength (UTS) | Yield Strength (0.2% off.) | Elongation (A%) | Hardness |

|---|---|---|---|---|

| Solution Annealed (soft) | ≈ 620 MPa (min) / ~90 ksi | ≈ 275 MPa (min) / ~40 ksi | ≥ 30% (typ.) | HRB ≤ 85 (typ.) |

| Aged (precipitation-hardened) | ≈ 760 – 1100 MPa (depends on aging) | ≈ 380 – 760 MPa (depends on aging) | ≈ 12 – 25% (typ.) | Rockwell C ~27–37 (typ., depending on temper) |

Equivalent / Cross Reference

| Designation System | Equivalent |

|---|---|

| UNS | N05500 |

| DIN / W.Nr. | 2.4375 |

| Trade Name | Monel K-500 (Alloy K-500) |

| BS / Other | BS NA18 (approx. cross reference) |

Frequently Asked Questions (FAQ)

Q: What is Monel K-500 best suited for?

Monel K-500 is ideal where high corrosion resistance (similar to Monel 400) must be combined with improved strength and fatigue resistance — e.g., subsea components, pump shafts, high-pressure fittings, and marine hardware.

Q: How does heat treatment affect Monel K-500 properties?

Monel K-500 is solution-annealed and then aged (precipitation hardening) to develop high strength. The aging temperature and time control final tensile/yield strengths and toughness — aged condition yields much higher strength but reduced elongation compared with annealed condition.

Q: Why choose a lapped joint flange?

Lapped joint flanges (with a loose backing ring) permit rotation and easier alignment during installation, which is helpful in lined piping, complex skid assemblies, or systems that require frequent repositioning or dismantling.

Q: Do you provide certification and third-party inspection?

Yes. Synergy Engineering Solution supplies Material Test Reports (MTRs), heat treatment records and can arrange third-party inspection and special packaging for export to Oman, Qatar, Saudi Arabia, UAE, Kuwait, Spain, Germany, USA, Canada, Africa and other destinations.

In order to alter the physical and mechanical characteristics of metal without altering its original shape and size, we offer a variety of heat treatment services, including hydrogen heat treatment, HIC testing, blasting and painting, cutting, arc welding, epoxy cutting, PMI testing, hydro testing, NACE testing, and SSC testing. Although heat treatment is frequently linked to a metal's increased strength, it can also be used to change specific manufacturability goals, such enhancing machinability, formability, ductility, etc. The metal and heavy manufacturing sectors use our services. Customers have expressed great pleasure with our services' precision, efficacy, cost, and prompt delivery.

Flanges Testing Methods

Flanges Applications

We supply Pipes Worldwide.

Exporting Steel Pipes & Tubes to over 60 countries including Afghanistan, Albania, Andorra, Angloa, Austria, Australia, Bahrain, Bangladesh, Bhutan, Brazil, Brunei, Belarus, Belgium, Bulgaria, Cambodia, China, Cyprus, Croatia, Czech Republic, Canada, Denmark, Estonia, Egypt, Finland, France, Germany, Greece, Georgia, Hungary, Iceland, Ireland, Italy, Indonesia, Iran, Iraq, Israel, Japan, Jordan, Kazakhstan, Kuwait, Kyrgyzstan, Lebanon, Latvia, Latin America, Liechtenstein, Lithuania, Luxembourg, Malta, Madagascar, Mexico, Moldova, Monaco, Malaysia, Maldives, Mongolia, Myanmar (Burma), Nepal, New Zealand, North Korea, Netherlands, Norway, Nigeria, Oman, Poland, Portugal, Pakistan, Palestine, Philippines, Qatar, Russia, Romania, Russia, San Marino, Serbia and Montenegro, Slovakia, Slovenia, Spain, Sweden, Switzerland, Saudi Arabia, Singapore, South Korea, South Africa, Sri Lanka, Sudan, Syria, Taiwan, Tanzania, Tajikistan, Thailand, Turkey, Turkmenistan, Ukraine, United Kingdom, United Arab Emirates (UAE), Uzbekistan, Venezuela, Vietnam, Yemen, etc.