UNS N06601 Inconel 601 Plate Flanges Manufacturer Stockist Exporter

- Home

- UNS N06601 Inconel 601 Plate Flanges

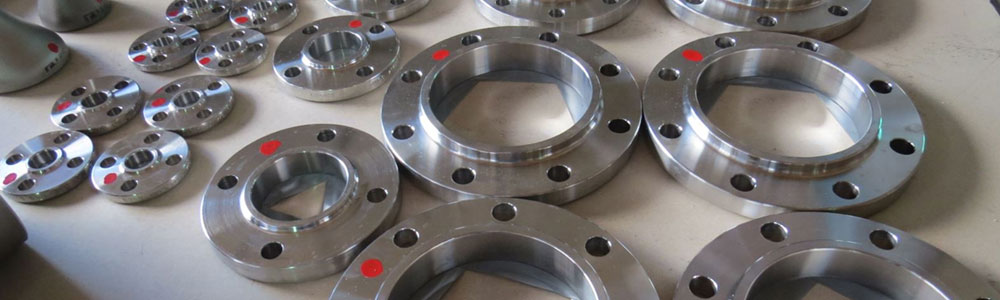

We are manufacturers, stockist and exporters of UNS N06601 Inconel 601 Plate Flanges in Mumbai.

Synergy Engineering Solution is a trusted manufacturer, stockist, and exporter of UNS N06601 Inconel 601 Plate Flanges, serving industries in Oman, Qatar, Saudi Arabia, UAE, Kuwait, Spain, Germany, the USA, Canada, and across various regions in Africa and worldwide. Inconel 601 is a nickel-chromium alloy renowned for its excellent resistance to high-temperature oxidation and corrosion. These properties make it an ideal material for manufacturing high-performance plate flanges that can withstand extreme operating conditions.

The Inconel 601 Plate Flanges manufactured by Synergy Engineering Solution are designed and produced in compliance with international standards such as ASTM B564 and ASME SB564. Available in multiple types including weld neck, slip-on, blind, threaded, socket weld, and lap joint, these flanges are offered in sizes ranging from ½ inch to 72 inches, with pressure ratings from 150# to 2500#. With advanced production facilities and strict quality control measures, Synergy ensures that every flange meets precise dimensional accuracy and reliability for critical applications.

UNS N06601, also referred to as Inconel 601, is primarily composed of nickel and chromium, with added aluminum for enhanced oxidation resistance. This unique composition provides outstanding resistance to spalling and scaling at elevated temperatures up to 1200°C (2200°F). Unlike many other alloys, Inconel 601 maintains mechanical strength and resists carburization and sulfidation in challenging environments, which is vital for industries operating under fluctuating thermal conditions.

The Inconel 601 Plate Flanges exhibit impressive mechanical properties including high tensile strength, excellent creep resistance, and good fatigue strength even at elevated temperatures. Their corrosion resistance extends to a wide range of environments including neutral and oxidizing atmospheres, making them suitable for chemical processing, power generation, petrochemicals, and furnace equipment. These features ensure long service life and minimal maintenance requirements, even in aggressive industrial environments.

Types Of Flanges manufacturer

Due to their exceptional durability, Inconel 601 Plate Flanges supplied by Synergy Engineering Solution are widely used in furnace construction, gas turbines, petrochemical plants, thermal processing equipment, heat exchangers, and aerospace applications. Their ability to resist oxidation and thermal shock under continuous operation makes them indispensable in industries requiring reliable and heat-resistant flanges.

As a global supplier, Synergy Engineering Solution exports UNS N06601 Inconel 601 Plate Flanges with full export documentation, including EN 10204 3.1 Mill Test Certificates and third-party inspection reports. With a robust supply chain, Synergy caters to industries across the Middle East, Europe, North America, and Africa, delivering premium-quality flanges with international packaging standards and timely delivery. This dedication to quality and global reach has established Synergy as a reliable partner in high-performance alloy solutions.

UNS N06601 Inconel 601 Plate Flanges

Specifications

| Standard | ASTM B564 / ASME SB564 |

|---|---|

| Size Range | ½" to 72" |

| Pressure Rating | 150# to 2500# |

| Flange Types | Weld Neck, Slip On, Socket Weld, Blind, Threaded, Lap Joint, Reducing, Orifice |

| Face Type | Raised Face (RF), Flat Face (FF), Ring Type Joint (RTJ) |

Chemical Composition

| Element | Content (%) |

|---|---|

| Nickel (Ni) | 58.0 – 63.0 |

| Chromium (Cr) | 21.0 – 25.0 |

| Iron (Fe) | Balance |

| Aluminum (Al) | 1.0 – 1.7 |

| Carbon (C) | 0.10 max |

| Manganese (Mn) | 1.0 max |

| Silicon (Si) | 0.5 max |

| Sulfur (S) | 0.015 max |

Mechanical Properties

| Property | Value |

|---|---|

| Tensile Strength | 550 MPa (80,000 psi) |

| Yield Strength (0.2% Offset) | 240 MPa (35,000 psi) |

| Elongation | 30 – 40% |

| Hardness | 85 HRB max |

| Service Temperature | Up to 1200°C (2200°F) |

Equivalent Grades

| Standard | Grade |

|---|---|

| UNS | N06601 |

| Werkstoff Nr. | 2.4851 |

| EN | NiCr23Fe |

| JIS | NCF 601 |

| BS | NA 61 |

Frequently Asked Questions (FAQ)

Q: What are the key advantages of Inconel 601 Plate Flanges?

Inconel 601 Plate Flanges provide excellent resistance to oxidation, carburization, and sulfidation at high temperatures up to 1200°C, ensuring superior durability.

Q: Are these flanges suitable for furnace and thermal processing equipment?

Yes, Inconel 601 is widely used in furnace construction, burners, and other high-temperature equipment because of its outstanding thermal resistance.

Q: Can Synergy Engineering deliver custom flange sizes?

Yes, we manufacture custom flange sizes, drilling, and face finishes as per client requirements and international standards.

Q: What certifications are supplied with Inconel 601 Plate Flanges?

We provide EN 10204 3.1 Mill Test Certificates, third-party inspection reports, and complete export documentation with every shipment.

Q: Where do you export Inconel 601 Plate Flanges?

We export globally including Oman, Qatar, Saudi Arabia, UAE, Kuwait, Spain, Germany, USA, Canada, and various African regions.

In order to alter the physical and mechanical characteristics of metal without altering its original shape and size, we offer a variety of heat treatment services, including hydrogen heat treatment, HIC testing, blasting and painting, cutting, arc welding, epoxy cutting, PMI testing, hydro testing, NACE testing, and SSC testing. Although heat treatment is frequently linked to a metal's increased strength, it can also be used to change specific manufacturability goals, such enhancing machinability, formability, ductility, etc. The metal and heavy manufacturing sectors use our services. Customers have expressed great pleasure with our services' precision, efficacy, cost, and prompt delivery.

Flanges Testing Methods

Flanges Applications

We supply Pipes Worldwide.

Exporting Steel Pipes & Tubes to over 60 countries including Afghanistan, Albania, Andorra, Angloa, Austria, Australia, Bahrain, Bangladesh, Bhutan, Brazil, Brunei, Belarus, Belgium, Bulgaria, Cambodia, China, Cyprus, Croatia, Czech Republic, Canada, Denmark, Estonia, Egypt, Finland, France, Germany, Greece, Georgia, Hungary, Iceland, Ireland, Italy, Indonesia, Iran, Iraq, Israel, Japan, Jordan, Kazakhstan, Kuwait, Kyrgyzstan, Lebanon, Latvia, Latin America, Liechtenstein, Lithuania, Luxembourg, Malta, Madagascar, Mexico, Moldova, Monaco, Malaysia, Maldives, Mongolia, Myanmar (Burma), Nepal, New Zealand, North Korea, Netherlands, Norway, Nigeria, Oman, Poland, Portugal, Pakistan, Palestine, Philippines, Qatar, Russia, Romania, Russia, San Marino, Serbia and Montenegro, Slovakia, Slovenia, Spain, Sweden, Switzerland, Saudi Arabia, Singapore, South Korea, South Africa, Sri Lanka, Sudan, Syria, Taiwan, Tanzania, Tajikistan, Thailand, Turkey, Turkmenistan, Ukraine, United Kingdom, United Arab Emirates (UAE), Uzbekistan, Venezuela, Vietnam, Yemen, etc.