UNS N06601 Inconel 601 Threaded Flanges Manufacturer Stockist Exporter

- Home

- UNS N06601 Inconel 601 Threaded Flanges

We are manufacturers, stockist and exporters of UNS N06601 Inconel 601 Threaded Flanges in Mumbai.

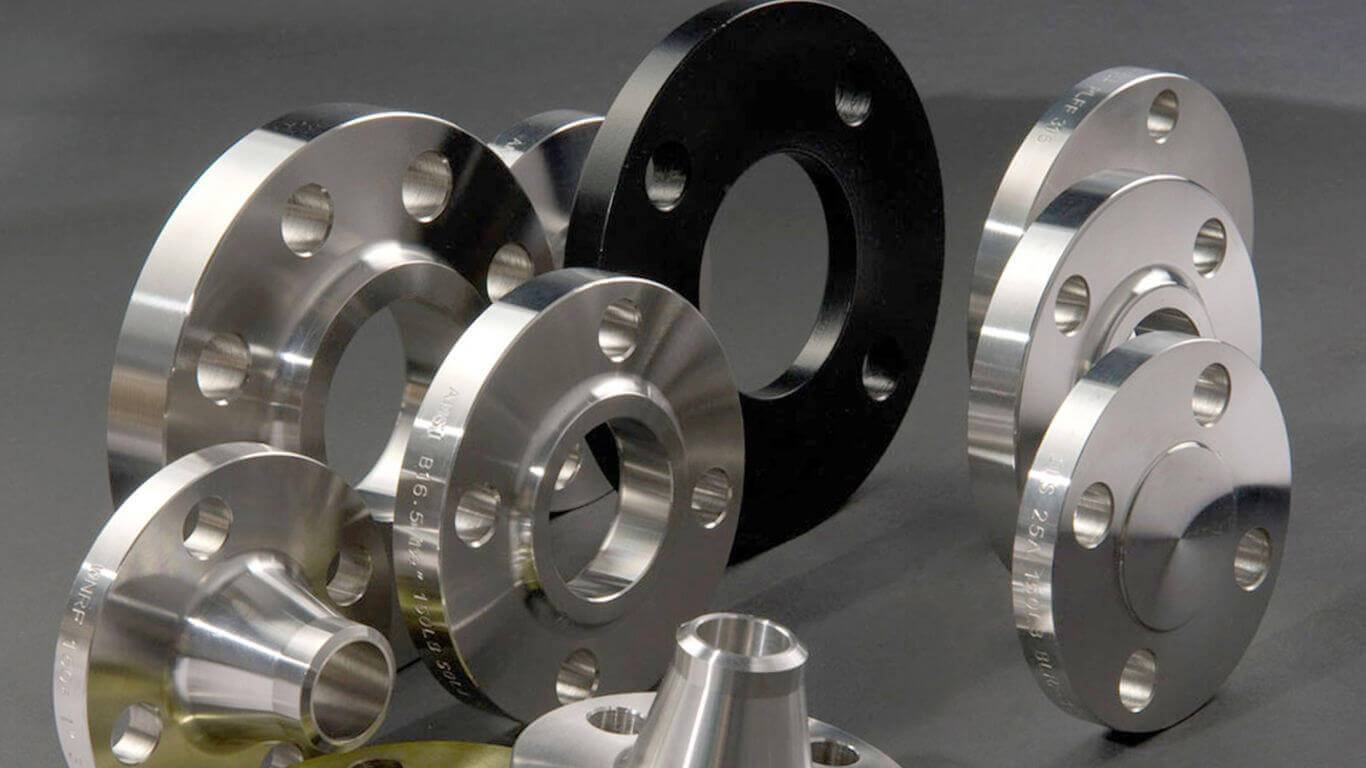

UNS N06601 Inconel 601 Threaded Flanges are high-temperature, corrosion-resistant components made from a nickel-chromium alloy with added aluminum. This combination offers excellent resistance to oxidation and scaling at elevated temperatures, as well as superior mechanical strength and structural stability. Inconel 601 is particularly effective in thermal cycling and carburizing environments, making it ideal for threaded flange applications in high-temperature industrial systems. The threaded design allows for easy assembly and disassembly without welding, which is especially valuable in piping systems requiring frequent maintenance or access.

Synergy Engineering Solution is a reliable manufacturer, stockist, and exporter of UNS N06601 Inconel 601 Threaded Flanges, providing high-quality flanges built to meet stringent international standards like ASTM B564 and ASME SB564. Utilizing advanced forging and machining processes, Synergy delivers flanges with precise dimensional tolerances, exceptional surface finishes, and proven performance in aggressive operating environments. Their products are designed to withstand long-term exposure to extreme heat, corrosion, and pressure variations.

As a global exporter, Synergy Engineering Solution supplies UNS N06601 Inconel 601 Threaded Flanges to clients in key markets such as Oman, Qatar, Saudi Arabia, UAE, Kuwait, Spain, Germany, the USA, and Canada, in addition to serving customers across Africa and other international regions. Their robust logistics infrastructure ensures timely and secure delivery, while their engineering expertise enables customized solutions for complex project needs in industries like petrochemical, aerospace, marine, and power generation.

The properties of Inconel 601 make it particularly well-suited for use in applications involving extreme heat and oxidizing atmospheres, such as furnace components, heat-treating baskets, radiant tubes, and exhaust systems. It retains its strength and oxidation resistance even in prolonged high-temperature exposure, while the aluminum content enhances its performance in oxidizing environments. The threaded connection simplifies installation in systems where welding is not feasible or desired.

Types Of Flanges manufacturer

Customers choose Synergy Engineering Solution for their proven track record in delivering top-grade materials and technical support. Whether for high-pressure steam systems in the Middle East or heat-resistant systems in European industrial plants, Synergy’s Inconel 601 threaded flanges are trusted by engineers and procurement teams for their durability and efficiency. The company’s commitment to quality, timely service, and customer satisfaction reinforces its reputation as a preferred supplier in the global market.

UNS N06601 Inconel 601 Threaded Flanges from Synergy Engineering Solution provide outstanding performance in extreme temperature and corrosive environments. Backed by a global supply chain and technical expertise, Synergy delivers tailored solutions for critical applications, earning the trust of industries worldwide seeking reliability, performance, and long service life in high-alloy piping components.

Specifications of UNS N06601 Inconel 601 Threaded Flanges

| Specification | Details |

|---|---|

| Material Grade | UNS N06601 / Inconel 601 |

| Standard Specifications | ASTM B564 / ASME SB564 |

| Flange Type | Threaded Flanges (Screwed Flanges) |

| Size Range | 1/2" to 24" (DN15 to DN600) |

| Pressure Ratings | Class 150#, 300#, 600#, 900#, 1500#, 2500# |

| Dimensions Standard | ASME B16.5, ANSI B16.5, DIN, EN, JIS, BS |

| Face Types | Raised Face (RF), Flat Face (FF), Ring Type Joint (RTJ) |

| Thread Standards | NPT, BSP, BSPT |

| Temperature Range | -196°C to 1200°C |

| Corrosion Resistance | Excellent in oxidizing and high-temperature environments |

| Manufacturing Method | Forged / CNC Machined |

| Surface Finish | As per requirement: Stock finish, Serrated finish, Smooth finish |

| Application Industries | Furnace Equipment, Chemical Processing, Aerospace, Marine, Petrochemical |

Chemical Properties of UNS N06601 Inconel 601 Threaded Flanges

| Element | Minimum (%) | Maximum (%) | Remarks |

|---|---|---|---|

| Nickel (Ni) | 58.0 | 63.0 | Base element; provides high-temperature strength and corrosion resistance |

| Chromium (Cr) | 21.0 | 25.0 | Enhances oxidation resistance at high temperatures |

| Iron (Fe) | Balance | — | Acts as balancing element |

| Aluminum (Al) | 1.0 | 1.7 | Improves oxidation and scaling resistance |

| Carbon (C) | — | 0.10 | Controlled to maintain strength and prevent embrittlement |

| Manganese (Mn) | — | 1.00 | Improves hot workability |

| Silicon (Si) | — | 0.50 | Enhances oxidation resistance |

| Sulfur (S) | — | 0.015 | Kept low to ensure good ductility and weldability |

| Copper (Cu) | — | 1.00 | Present in trace amounts, not a major contributor |

Mechanical properties of UNS N06601 Inconel 601 Threaded Flanges

| Property | Value | Unit | Remarks |

|---|---|---|---|

| Tensile Strength | ≥ 550 | MPa | Minimum at room temperature (per ASTM B564) |

| Yield Strength (0.2%) | ≥ 205 | MPa | Good structural strength under load |

| Elongation | ≥ 30 | % | Indicates good ductility |

| Hardness (Rockwell B) | ≤ 85 | HRB | Soft enough for machining, tough in service |

| Modulus of Elasticity | ~206 | GPa | At room temperature |

| Poisson’s Ratio | 0.30 | — | Dimensionless |

| Density | 8.11 | g/cm³ | Slightly less dense than Inconel 600 due to aluminum content |

| Melting Range | 1360 – 1411 | °C | Equivalent to ~2480 – 2572 °F |

| Thermal Conductivity | 15.2 | W/m·K | At 100°C, performs well in heat transfer |

| Electrical Resistivity | 1.25 | µΩ·m | Higher due to alloying elements |

In order to alter the physical and mechanical characteristics of metal without altering its original shape and size, we offer a variety of heat treatment services, including hydrogen heat treatment, HIC testing, blasting and painting, cutting, arc welding, epoxy cutting, PMI testing, hydro testing, NACE testing, and SSC testing. Although heat treatment is frequently linked to a metal's increased strength, it can also be used to change specific manufacturability goals, such enhancing machinability, formability, ductility, etc. The metal and heavy manufacturing sectors use our services. Customers have expressed great pleasure with our services' precision, efficacy, cost, and prompt delivery.

Flanges Testing Methods

Flanges Applications

We supply Pipes Worldwide.

Exporting Steel Pipes & Tubes to over 60 countries including Afghanistan, Albania, Andorra, Angloa, Austria, Australia, Bahrain, Bangladesh, Bhutan, Brazil, Brunei, Belarus, Belgium, Bulgaria, Cambodia, China, Cyprus, Croatia, Czech Republic, Canada, Denmark, Estonia, Egypt, Finland, France, Germany, Greece, Georgia, Hungary, Iceland, Ireland, Italy, Indonesia, Iran, Iraq, Israel, Japan, Jordan, Kazakhstan, Kuwait, Kyrgyzstan, Lebanon, Latvia, Latin America, Liechtenstein, Lithuania, Luxembourg, Malta, Madagascar, Mexico, Moldova, Monaco, Malaysia, Maldives, Mongolia, Myanmar (Burma), Nepal, New Zealand, North Korea, Netherlands, Norway, Nigeria, Oman, Poland, Portugal, Pakistan, Palestine, Philippines, Qatar, Russia, Romania, Russia, San Marino, Serbia and Montenegro, Slovakia, Slovenia, Spain, Sweden, Switzerland, Saudi Arabia, Singapore, South Korea, South Africa, Sri Lanka, Sudan, Syria, Taiwan, Tanzania, Tajikistan, Thailand, Turkey, Turkmenistan, Ukraine, United Kingdom, United Arab Emirates (UAE), Uzbekistan, Venezuela, Vietnam, Yemen, etc.