UNS N07718 Inconel 718 Spectacle Blind Flanges Manufacturer Stockist Exporter

- Home

- UNS N07718 Inconel 718 Spectacle Blind Flanges

We are manufacturers, stockist and exporters of UNS N07718 Inconel 718 Spectacle Blind Flanges in Mumbai.

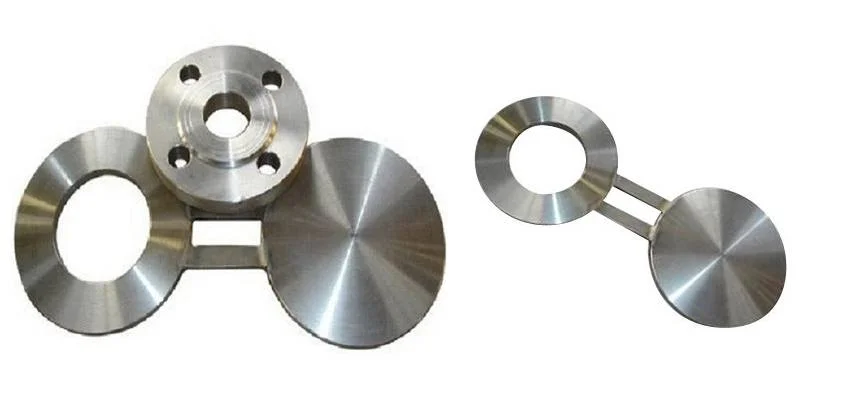

UNS N07718 Inconel 718 Spectacle Blind Flanges are high-performance flanges manufactured from Inconel 718, a nickel-chromium alloy renowned for its exceptional strength, corrosion resistance, and ability to withstand extreme temperatures. Synergy Engineering Solution is a trusted manufacturer, stockist, and exporter of these flanges, ensuring high-quality products that meet international standards. The Spectacle Blind Flange design is specifically engineered to isolate sections of piping systems, allowing for safe maintenance and pressure testing without disrupting operations.

Our Inconel 718 Spectacle Blind Flanges are extensively used in critical industries such as aerospace, power generation, petrochemical, oil & gas, and marine applications. The flanges provide excellent resistance to oxidation, pitting, and stress corrosion cracking, making them ideal for high-pressure and high-temperature environments. Their durable construction ensures longevity even under demanding operating conditions, reducing downtime and maintenance costs.

Synergy Engineering Solution prides itself on its global reach, exporting Inconel 718 Spectacle Blind Flanges to countries including Oman, Qatar, Saudi Arabia, UAE, Kuwait, Spain, Germany, the USA, Canada, and various regions in Africa. By maintaining a large stock inventory, the company ensures timely delivery and availability of flanges in diverse sizes, pressure ratings, and dimensions as per ASME B16.5 / B16.47 standards.

The manufacturing process at Synergy Engineering Solution emphasizes precision and quality. Each flange undergoes rigorous testing, including dimensional inspection, chemical composition analysis, and mechanical property verification, to guarantee compliance with international quality standards. This meticulous approach ensures that the Inconel 718 Spectacle Blind Flanges perform reliably in critical applications where safety and performance are paramount.

Types Of Flanges manufacturer

In addition to standard products, Synergy Engineering Solution offers customized solutions tailored to client requirements, including special sizes, pressure classes, and surface finishes. The company’s experienced engineering team provides technical support to help clients select the most suitable flanges for their specific applications, ensuring both efficiency and safety in operations.

With a commitment to excellence, Synergy Engineering Solution has established itself as a leading exporter and supplier of Inconel 718 Spectacle Blind Flanges worldwide. Clients across industries trust the company for its superior product quality, timely delivery, competitive pricing, and responsive customer support, making it a preferred partner for high-performance nickel alloy flanges globally.

UNS N07718 Inconel 718 Spectacle Blind Flanges

Synergy Engineering Solution is a trusted manufacturer, stockist, and exporter of high-quality UNS N07718 Inconel 718 Spectacle Blind Flanges. These flanges are designed for critical industrial applications requiring excellent corrosion resistance, high strength, and durability under extreme temperatures.

Specifications

| Type | Standard | Size | Pressure | Face Type |

|---|---|---|---|---|

| Inconel 718 Spectacle Blind Flanges | ASME B16.5 / B16.47 | 1/2" to 60" | 150# to 2500# | RF, RTJ, FF, Lapped Joint |

Chemical Composition (%)

| Element | Percentage |

|---|---|

| Nickel (Ni) | 50-55 |

| Chromium (Cr) | 17-21 |

| Cobalt (Co) | ≤1 |

| Molybdenum (Mo) | 2.8-3.3 |

| Niobium (Nb + Ta) | 4.75-5.5 |

| Iron (Fe) | Balance |

| Titanium (Ti) | 0.65-1.15 |

| Aluminium (Al) | 0.2-0.8 |

| Carbon (C) | 0.08 max |

| Manganese (Mn) | 0.35 max |

| Silicon (Si) | 0.35 max |

| Phosphorus (P) | 0.015 max |

| Sulfur (S) | 0.015 max |

Mechanical Properties

| Property | Value |

|---|---|

| Tensile Strength | 140 ksi min |

| Yield Strength | 75 ksi min |

| Elongation | 12% min |

| Hardness | ≤ 321 HB |

| Temperature Range | -252°C to 700°C |

Equivalent Grades

| Standard | Equivalent Grade |

|---|---|

| AISI / ASTM | UNS N07718 |

| DIN | 2.4668 / XNiCrMoNb21-10-1 |

| EN | Inconel 718 |

| JIS | NCF 718 |

Frequently Asked Questions (FAQ)

Q: What are the main applications of Inconel 718 Spectacle Blind Flanges?

These flanges are widely used in aerospace, petrochemical, oil & gas, marine, and power generation industries due to their high strength and corrosion resistance.

Q: Which standards do your Inconel 718 flanges meet?

Our flanges comply with ASME B16.5, B16.47, and other international standards to ensure quality and performance.

Q: Can you supply custom sizes and pressure ratings?

Yes, we offer customized dimensions, pressure classes, and face types according to client requirements.

Q: Which countries do you export to?

We export to Oman, Qatar, Saudi Arabia, UAE, Kuwait, Spain, Germany, USA, Canada, and multiple regions in Africa.

In order to alter the physical and mechanical characteristics of metal without altering its original shape and size, we offer a variety of heat treatment services, including hydrogen heat treatment, HIC testing, blasting and painting, cutting, arc welding, epoxy cutting, PMI testing, hydro testing, NACE testing, and SSC testing. Although heat treatment is frequently linked to a metal's increased strength, it can also be used to change specific manufacturability goals, such enhancing machinability, formability, ductility, etc. The metal and heavy manufacturing sectors use our services. Customers have expressed great pleasure with our services' precision, efficacy, cost, and prompt delivery.

Flanges Testing Methods

Flanges Applications

We supply Pipes Worldwide.

Exporting Steel Pipes & Tubes to over 60 countries including Afghanistan, Albania, Andorra, Angloa, Austria, Australia, Bahrain, Bangladesh, Bhutan, Brazil, Brunei, Belarus, Belgium, Bulgaria, Cambodia, China, Cyprus, Croatia, Czech Republic, Canada, Denmark, Estonia, Egypt, Finland, France, Germany, Greece, Georgia, Hungary, Iceland, Ireland, Italy, Indonesia, Iran, Iraq, Israel, Japan, Jordan, Kazakhstan, Kuwait, Kyrgyzstan, Lebanon, Latvia, Latin America, Liechtenstein, Lithuania, Luxembourg, Malta, Madagascar, Mexico, Moldova, Monaco, Malaysia, Maldives, Mongolia, Myanmar (Burma), Nepal, New Zealand, North Korea, Netherlands, Norway, Nigeria, Oman, Poland, Portugal, Pakistan, Palestine, Philippines, Qatar, Russia, Romania, Russia, San Marino, Serbia and Montenegro, Slovakia, Slovenia, Spain, Sweden, Switzerland, Saudi Arabia, Singapore, South Korea, South Africa, Sri Lanka, Sudan, Syria, Taiwan, Tanzania, Tajikistan, Thailand, Turkey, Turkmenistan, Ukraine, United Kingdom, United Arab Emirates (UAE), Uzbekistan, Venezuela, Vietnam, Yemen, etc.