UNS N07718 Inconel 718 Threaded Flanges Manufacturer Stockist Exporter

- Home

- UNS N07718 Inconel 718 Threaded Flanges

We are manufacturers, stockist and exporters of UNS N07718 Inconel 718 Threaded Flanges in Mumbai.

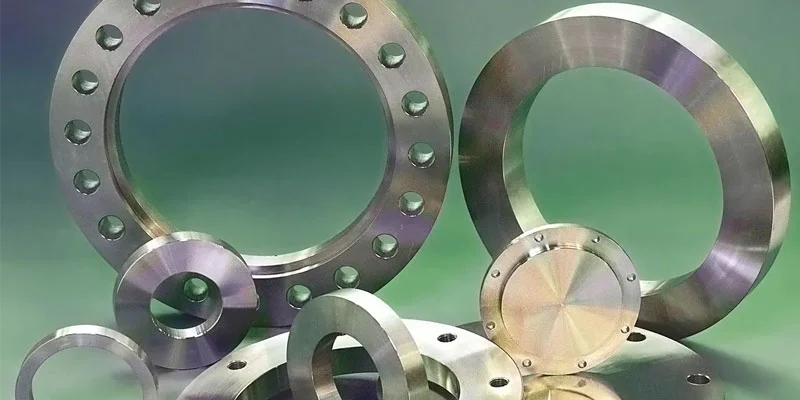

UNS N07718 Inconel 718 Threaded Flanges are high-performance components engineered for demanding industrial applications, especially in environments that involve high pressure and temperature. Inconel 718, designated by the UNS number N07718, is a precipitation-hardenable nickel-chromium alloy known for its excellent strength and corrosion resistance. These threaded flanges are ideal for systems that require leak-proof, easy-to-install connections without the need for welding. Due to their superior mechanical properties and oxidation resistance, they are widely used in aerospace, marine, oil and gas, and chemical processing industries.

Synergy Engineering Solution is a leading manufacturer, stockist, and exporter of UNS N07718 Inconel 718 Threaded Flanges, offering a wide range of sizes, pressure ratings, and specifications to meet international standards. With advanced manufacturing facilities and a dedicated quality control team, Synergy Engineering ensures that every flange produced adheres to stringent industry requirements. Their expertise in working with nickel alloys, especially Inconel 718, enables them to deliver products that are reliable, durable, and high-performing under extreme conditions.

The company's flanges are widely exported to major markets including Oman, Qatar, Saudi Arabia, UAE, and Kuwait, where the demand for corrosion-resistant and high-temperature materials is high due to the harsh environmental conditions in petrochemical and offshore operations. In addition, Synergy Engineering Solution has established a strong presence in Spain, Germany, the USA, Canada, and across Africa, reinforcing its position as a trusted global supplier of threaded flange solutions. Their international distribution network ensures timely delivery and customer support worldwide.

UNS N07718 Inconel 718 Threaded Flanges are preferred in critical operations due to their excellent fatigue strength, weldability, and resistance to post-weld cracking. The material's ability to withstand extreme conditions makes it a preferred choice in industries like aerospace engineering, nuclear reactors, and gas turbines. These flanges are also known for their long service life, reducing the frequency of replacements and downtime in industrial systems.

Types Of Flanges manufacturer

As a stockist, Synergy Engineering Solution maintains a comprehensive inventory of Inconel 718 threaded flanges to meet urgent project needs and bulk requirements. Their commitment to quality and customer satisfaction, combined with competitive pricing, has earned them a loyal client base across diverse sectors. The company also offers custom solutions tailored to the specifications and standards required by various international clients.

UNS N07718 Inconel 718 Threaded Flanges offered by Synergy Engineering Solution are a reliable and high-quality choice for critical industrial applications. With a global export reach and a reputation for excellence, the company continues to supply cutting-edge solutions to customers across the Middle East, Europe, North America, and Africa. Whether for oil refineries, power plants, or marine projects, these flanges provide superior performance and durability in the world’s toughest environments.

Specifications of UNS N07718 Inconel 718 Threaded Flanges

| Specification | Details |

|---|---|

| Material | Inconel 718 (UNS N07718) |

| Type | Threaded Flanges (Screwed Flanges) |

| Standard Specifications | ASTM B564 / ASME SB564 |

| Grade | Inconel Alloy 718 |

| Size Range | ½” to 24” (DN15 to DN600) or as per customer requirement |

| Pressure Ratings (Class) | 150#, 300#, 600#, 900#, 1500#, 2500# |

| Thread Type | NPT (National Pipe Thread), BSP (British Standard Pipe), as specified |

| Facing Type | Raised Face (RF), Flat Face (FF), Ring Type Joint (RTJ) |

| Temperature Range | Up to 1300°F (705°C) |

| Tensile Strength | 135 ksi (930 MPa) minimum |

| Yield Strength (0.2% offset) | 70 ksi (480 MPa) minimum |

| Hardness | Rockwell C35 maximum |

| Corrosion Resistance | Excellent in high-temperature and corrosive environments |

| Applications | Oil & Gas, Aerospace, Power Generation, Marine, Chemical Processing |

| Manufacturing Process | Forged, Machined, Heat Treated |

| Certification | EN 10204 3.1 / 3.2, NACE MR0175, ISO, PED, etc. |

| Origin | Manufactured and Supplied by Synergy Engineering Solution |

Chemical Properties of UNS N07718 Inconel 718 Threaded Flanges

| Element | Composition (%) |

|---|---|

| Nickel (Ni) | 50.0 – 55.0 |

| Chromium (Cr) | 17.0 – 21.0 |

| Iron (Fe) | Balance |

| Niobium (Nb) + Tantalum (Ta) | 4.75 – 5.50 |

| Molybdenum (Mo) | 2.80 – 3.30 |

| Titanium (Ti) | 0.65 – 1.15 |

| Aluminum (Al) | 0.20 – 0.80 |

| Cobalt (Co) | ≤ 1.0 |

| Manganese (Mn) | ≤ 0.35 |

| Silicon (Si) | ≤ 0.35 |

| Carbon (C) | ≤ 0.08 |

| Phosphorus (P) | ≤ 0.015 |

| Sulfur (S) | ≤ 0.015 |

| Boron (B) | ≤ 0.006 |

| Copper (Cu) | ≤ 0.30 |

Mechanical properties of UNS N07718 Inconel 718 Threaded Flanges

| Property | Value |

|---|---|

| Tensile Strength (Ultimate) | ≥ 135 ksi (930 MPa) |

| Yield Strength (0.2% Offset) | ≥ 70 ksi (480 MPa) |

| Elongation at Break | ≥ 12% |

| Hardness | ≤ Rockwell C35 (Rc 35) |

| Modulus of Elasticity | ~ 207 GPa (30 x 10³ ksi) |

| Impact Strength (Charpy V-Notch) | Good (material remains tough at cryogenic and elevated temperatures) |

| Fatigue Strength | Excellent (suitable for cyclic loading) |

| Operating Temperature Range | -423°F to +1300°F (-253°C to +705°C) |

| Creep Resistance | High (suitable for long-term high-temperature service) |

In order to alter the physical and mechanical characteristics of metal without altering its original shape and size, we offer a variety of heat treatment services, including hydrogen heat treatment, HIC testing, blasting and painting, cutting, arc welding, epoxy cutting, PMI testing, hydro testing, NACE testing, and SSC testing. Although heat treatment is frequently linked to a metal's increased strength, it can also be used to change specific manufacturability goals, such enhancing machinability, formability, ductility, etc. The metal and heavy manufacturing sectors use our services. Customers have expressed great pleasure with our services' precision, efficacy, cost, and prompt delivery.

Flanges Testing Methods

Flanges Applications

We supply Pipes Worldwide.

Exporting Steel Pipes & Tubes to over 60 countries including Afghanistan, Albania, Andorra, Angloa, Austria, Australia, Bahrain, Bangladesh, Bhutan, Brazil, Brunei, Belarus, Belgium, Bulgaria, Cambodia, China, Cyprus, Croatia, Czech Republic, Canada, Denmark, Estonia, Egypt, Finland, France, Germany, Greece, Georgia, Hungary, Iceland, Ireland, Italy, Indonesia, Iran, Iraq, Israel, Japan, Jordan, Kazakhstan, Kuwait, Kyrgyzstan, Lebanon, Latvia, Latin America, Liechtenstein, Lithuania, Luxembourg, Malta, Madagascar, Mexico, Moldova, Monaco, Malaysia, Maldives, Mongolia, Myanmar (Burma), Nepal, New Zealand, North Korea, Netherlands, Norway, Nigeria, Oman, Poland, Portugal, Pakistan, Palestine, Philippines, Qatar, Russia, Romania, Russia, San Marino, Serbia and Montenegro, Slovakia, Slovenia, Spain, Sweden, Switzerland, Saudi Arabia, Singapore, South Korea, South Africa, Sri Lanka, Sudan, Syria, Taiwan, Tanzania, Tajikistan, Thailand, Turkey, Turkmenistan, Ukraine, United Kingdom, United Arab Emirates (UAE), Uzbekistan, Venezuela, Vietnam, Yemen, etc.