UNS N08800 Inconel 800 Blind BLRF Flanges Manufacturer Stockist Exporter

- Home

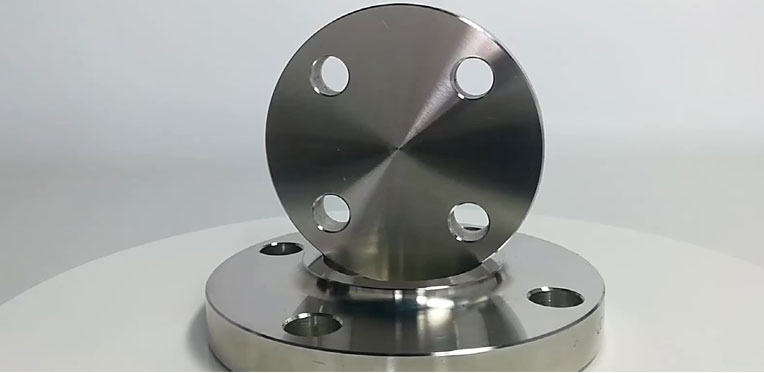

- UNS N08800 Inconel 800 Blind BLRF Flanges

We are manufacturers, stockist and exporters of UNS N08800 Inconel 800 Blind BLRF Flanges in Mumbai.

UNS N08800 Inconel 800 Blind BLRF Flanges are high-performance pipe components used to seal the end of piping systems in high-temperature and corrosive service environments. Manufactured from Incoloy 800, a nickel-iron-chromium alloy, these flanges offer excellent strength and resistance to oxidation and carburization at elevated temperatures. The Blind Raised Face (BLRF) design is solid with no center bore, making it ideal for isolating sections of pipe or pressure vessels for maintenance, inspection, or future expansion.

Synergy Engineering Solution is a trusted manufacturer, stockist, and exporter of UNS N08800 Inconel 800 Blind BLRF Flanges, delivering precision-engineered products that comply with global standards such as ASTM B564 and ASME B16.5. With modern production infrastructure and a commitment to quality, Synergy ensures its Incoloy 800 flanges deliver consistent performance, dimensional accuracy, and long service life in demanding applications.

Synergy Engineering Solution exports its UNS N08800 Inconel 800 Blind BLRF Flanges to a wide international market including Oman, Qatar, Saudi Arabia, UAE, Kuwait, Spain, Germany, the USA, Canada, and various regions throughout Africa and worldwide. These flanges are widely used in refineries, petrochemical plants, power generation facilities, and heat-treating equipment, where resistance to high temperatures and corrosive environments is critical.

Incoloy 800’s composition provides excellent resistance to chloride stress-corrosion cracking and intergranular attack, making it suitable for use in heat exchangers, boilers, and furnace components. The alloy maintains its mechanical stability even at elevated temperatures (up to 1100°F / 593°C), which is a key advantage in thermal processing applications. This makes UNS N08800 Inconel 800 Blind BLRF Flanges highly reliable under fluctuating temperature and pressure conditions.

Types Of Flanges manufacturer

Synergy Engineering Solution also offers value-added services such as custom machining, pressure class customization, and prompt delivery across international locations. Their dedicated engineering and logistics teams ensure technical compliance, timely support, and hassle-free export documentation, making them a preferred global supplier for industrial flange requirements.

In conclusion, UNS N08800 Inconel 800 Blind BLRF Flanges from Synergy Engineering Solution provide an ideal combination of durability, heat resistance, and corrosion performance. Backed by global reach and a strong focus on customer satisfaction, Synergy continues to be a leading provider of high-performance flanges for critical applications across industries worldwide.

Specifications of UNS N08800 Inconel 800 Blind BLRF Flanges

| Specification | Details |

|---|---|

| Product Name | UNS N08800 Inconel 800 Blind BLRF Flanges |

| Material Grade | Incoloy 800 (UNS N08800 / W.Nr. 1.4876) |

| Flange Type | Blind Raised Face (BLRF) |

| Manufacturing Standard | ASTM B564 / ASME SB564 |

| Size Range | ½” to 60” (DN15 to DN1500) |

| Pressure Rating | Class 150 to 2500 / PN6 to PN400 |

| Facing Type | Raised Face (RF), Flat Face (FF), Ring Type Joint (RTJ) |

| Dimensions Standard | ASME B16.5, ASME B16.47, MSS SP-44, DIN, EN, BS, ISO |

| Temperature Range | Up to 1100°F (593°C) |

| Heat Treatment | Solution Annealed |

| Corrosion Resistance | Excellent in high-temperature oxidizing and carburizing environments |

| Applications | Petrochemical, Power Generation, Furnace Equipment, Heat Exchangers |

| Testing & Certification | PMI, UT, RT, MTC as per EN 10204 3.1/3.2 |

Chemical Properties of UNS N08800 Inconel 800 Blind BLRF Flanges

| Element | Composition (%) |

|---|---|

| Nickel (Ni) | 30.0 – 35.0 |

| Chromium (Cr) | 19.0 – 23.0 |

| Iron (Fe) | 39.5 min (Balance) |

| Carbon (C) | 0.10 max |

| Aluminum (Al) | 0.15 – 0.60 |

| Titanium (Ti) | 0.15 – 0.60 |

| Manganese (Mn) | 1.5 max |

| Silicon (Si) | 1.0 max |

| Sulfur (S) | 0.015 max |

| Copper (Cu) | 0.75 max |

Mechanical properties of UNS N08800 Inconel 800 Blind BLRF Flanges

| Property | Value |

|---|---|

| Tensile Strength | ≥ 520 MPa (75 ksi) |

| Yield Strength (0.2%) | ≥ 205 MPa (30 ksi) |

| Elongation | ≥ 30% |

| Hardness (Brinell) | ≤ 200 HB |

| Modulus of Elasticity | 196 GPa (28.4 x 10³ ksi) |

| Density | 7.94 g/cm³ (0.287 lb/in³) |

| Melting Range | 1357 – 1385°C (2475 – 2525°F) |

| Creep Rupture Strength | Excellent up to 816°C (1500°F) |

| Impact Resistance | Good, with stable performance at elevated temperatures |

In order to alter the physical and mechanical characteristics of metal without altering its original shape and size, we offer a variety of heat treatment services, including hydrogen heat treatment, HIC testing, blasting and painting, cutting, arc welding, epoxy cutting, PMI testing, hydro testing, NACE testing, and SSC testing. Although heat treatment is frequently linked to a metal's increased strength, it can also be used to change specific manufacturability goals, such enhancing machinability, formability, ductility, etc. The metal and heavy manufacturing sectors use our services. Customers have expressed great pleasure with our services' precision, efficacy, cost, and prompt delivery.

Flanges Testing Methods

Flanges Applications

We supply Pipes Worldwide.

Exporting Steel Pipes & Tubes to over 60 countries including Afghanistan, Albania, Andorra, Angloa, Austria, Australia, Bahrain, Bangladesh, Bhutan, Brazil, Brunei, Belarus, Belgium, Bulgaria, Cambodia, China, Cyprus, Croatia, Czech Republic, Canada, Denmark, Estonia, Egypt, Finland, France, Germany, Greece, Georgia, Hungary, Iceland, Ireland, Italy, Indonesia, Iran, Iraq, Israel, Japan, Jordan, Kazakhstan, Kuwait, Kyrgyzstan, Lebanon, Latvia, Latin America, Liechtenstein, Lithuania, Luxembourg, Malta, Madagascar, Mexico, Moldova, Monaco, Malaysia, Maldives, Mongolia, Myanmar (Burma), Nepal, New Zealand, North Korea, Netherlands, Norway, Nigeria, Oman, Poland, Portugal, Pakistan, Palestine, Philippines, Qatar, Russia, Romania, Russia, San Marino, Serbia and Montenegro, Slovakia, Slovenia, Spain, Sweden, Switzerland, Saudi Arabia, Singapore, South Korea, South Africa, Sri Lanka, Sudan, Syria, Taiwan, Tanzania, Tajikistan, Thailand, Turkey, Turkmenistan, Ukraine, United Kingdom, United Arab Emirates (UAE), Uzbekistan, Venezuela, Vietnam, Yemen, etc.