UNS N08825 Inconel 825 Slip-on SORF Flanges Manufacturer Stockist Exporter

- Home

- UNS N08825 Inconel 825 Slip-on SORF Flanges

We are manufacturers, stockist and exporters of UNS N08825 Inconel 825 Slip-on SORF Flanges in Mumbai.

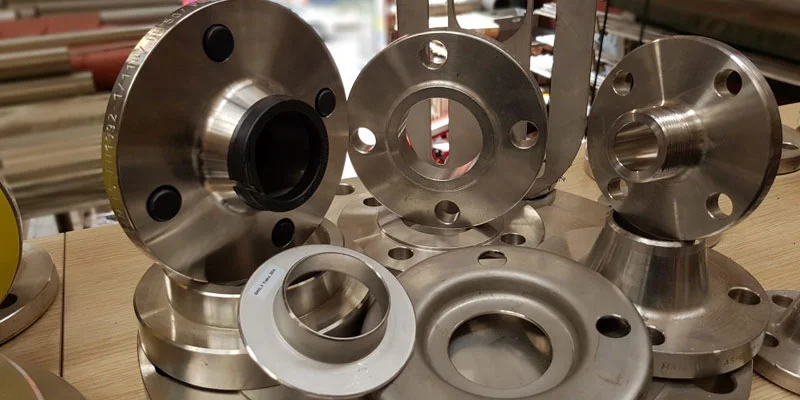

UNS N08825 Inconel 825 Slip-on SORF Flanges are a premium class of corrosion-resistant flanges widely used in critical environments such as chemical processing, marine engineering, and pollution control. Manufactured using Inconel 825—a nickel-iron-chromium alloy with additions of molybdenum, copper, and titanium—these flanges offer exceptional resistance to acidic and oxidizing environments, including sulfuric and phosphoric acids. The slip-on design ensures ease of installation, while the raised face (SORF) improves the seal integrity under pressure, making them a reliable choice for connecting pipes in demanding conditions.

Synergy Engineering Solution is a leading manufacturer, stockist, and exporter of UNS N08825 Inconel 825 Slip-on SORF Flanges, committed to delivering products that meet international standards such as ASME, ANSI, DIN, and EN. With advanced manufacturing capabilities and a robust quality control system, the company ensures precision engineering, high performance, and consistent reliability in every flange they produce. Their product range is available in various sizes, pressure ratings, and face types to meet diverse industrial requirements.

The company serves key oil & gas and industrial hubs in the Middle East, including Oman, Qatar, Saudi Arabia, the UAE, and Kuwait, where the harsh operating environments demand materials with excellent resistance to corrosion and stress cracking. In these regions, Synergy Engineering Solution has built a solid reputation for supplying high-performance flanges that support long-term operational reliability in refineries, offshore rigs, and chemical plants.

Beyond the Gulf, Synergy Engineering Solution exports Inconel 825 Slip-on SORF Flanges to Spain, Germany, and other European nations, where quality and compliance with stringent technical specifications are top priorities. Their products are also well-received in North America, especially in the USA and Canada, where industries such as wastewater treatment, pharmaceuticals, and nuclear energy rely on corrosion-resistant flanges for safe and efficient operations.

Types Of Flanges manufacturer

Expanding into emerging markets, the company is steadily growing its presence in Africa and other global regions, providing clients with not just flanges but full technical support, material traceability, and third-party inspection services. Their global logistics network ensures timely delivery, whether for large-scale industrial projects or small-volume requirements.

With a commitment to engineering excellence and customer satisfaction, Synergy Engineering Solution continues to be a trusted name in the global supply of UNS N08825 Inconel 825 Slip-on SORF Flanges. Their products are the preferred choice for industries requiring superior corrosion resistance, durability under pressure, and dependable performance in extreme environments.

Specifications of UNS N08825 Inconel 825 Slip-on SORF Flanges

| Specification | Details |

|---|---|

| Material Grade | UNS N08825 / Inconel 825 |

| Flange Type | Slip-on Flange with Raised Face (SORF) |

| Standards | ASME B16.5, ASME B16.47, ANSI B16.5, EN 1092-1, DIN, BS |

| Size Range | ½” to 48” (DN15 to DN1200) |

| Pressure Class | Class 150, 300, 600, 900, 1500, 2500 LB |

| Face Type | Raised Face (RF), Flat Face (FF), Ring Type Joint (RTJ) |

| Temperature Range | Up to 540°C (1000°F) |

| Corrosion Resistance | Excellent in sulfuric acid, phosphoric acid, and seawater environments |

| Manufacturing Process | Forged, Machined, Heat Treated |

| Applicable Industries | Chemical Processing, Oil & Gas, Marine, Pollution Control, Nuclear Plants |

| Testing & Certification | NACE MR0175, MTC EN 10204 3.1/3.2, IBR, Third-party inspection available |

| Surface Finish | Rust Preventive Coating, Black Paint, Custom Finishes Available |

| End Connection | Slip-on Weld Connection with matching bore |

Chemical Properties of UNS N08825 Inconel 825 Slip-on SORF Flanges

| Element | Composition (%) |

|---|---|

| Nickel (Ni) | 38.0 – 46.0 |

| Chromium (Cr) | 19.5 – 23.5 |

| Iron (Fe) | Balance |

| Molybdenum (Mo) | 2.5 – 3.5 |

| Copper (Cu) | 1.5 – 3.0 |

| Titanium (Ti) | 0.6 – 1.2 |

| Carbon (C) | ≤ 0.05 |

| Manganese (Mn) | ≤ 1.0 |

| Silicon (Si) | ≤ 0.5 |

| Aluminum (Al) | ≤ 0.2 |

| Sulfur (S) | ≤ 0.03 |

Mechanical properties of UNS N08825 Inconel 825 Slip-on SORF Flanges

| Property | Value |

|---|---|

| Tensile Strength (min) | 585 MPa (85 ksi) |

| Yield Strength (0.2% offset, min) | 220 MPa (32 ksi) |

| Elongation (min) | 30% |

| Hardness (Brinell) | ≤ 200 HB |

| Modulus of Elasticity | 196 GPa (28.4 × 10⁶ psi) |

| Melting Range | 1370 – 1400 °C (2500 – 2550 °F) |

| Density | 8.14 g/cm³ (0.294 lb/in³) |

| Impact Resistance | Good at both ambient and elevated temperatures |

In order to alter the physical and mechanical characteristics of metal without altering its original shape and size, we offer a variety of heat treatment services, including hydrogen heat treatment, HIC testing, blasting and painting, cutting, arc welding, epoxy cutting, PMI testing, hydro testing, NACE testing, and SSC testing. Although heat treatment is frequently linked to a metal's increased strength, it can also be used to change specific manufacturability goals, such enhancing machinability, formability, ductility, etc. The metal and heavy manufacturing sectors use our services. Customers have expressed great pleasure with our services' precision, efficacy, cost, and prompt delivery.

Flanges Testing Methods

Flanges Applications

We supply Pipes Worldwide.

Exporting Steel Pipes & Tubes to over 60 countries including Afghanistan, Albania, Andorra, Angloa, Austria, Australia, Bahrain, Bangladesh, Bhutan, Brazil, Brunei, Belarus, Belgium, Bulgaria, Cambodia, China, Cyprus, Croatia, Czech Republic, Canada, Denmark, Estonia, Egypt, Finland, France, Germany, Greece, Georgia, Hungary, Iceland, Ireland, Italy, Indonesia, Iran, Iraq, Israel, Japan, Jordan, Kazakhstan, Kuwait, Kyrgyzstan, Lebanon, Latvia, Latin America, Liechtenstein, Lithuania, Luxembourg, Malta, Madagascar, Mexico, Moldova, Monaco, Malaysia, Maldives, Mongolia, Myanmar (Burma), Nepal, New Zealand, North Korea, Netherlands, Norway, Nigeria, Oman, Poland, Portugal, Pakistan, Palestine, Philippines, Qatar, Russia, Romania, Russia, San Marino, Serbia and Montenegro, Slovakia, Slovenia, Spain, Sweden, Switzerland, Saudi Arabia, Singapore, South Korea, South Africa, Sri Lanka, Sudan, Syria, Taiwan, Tanzania, Tajikistan, Thailand, Turkey, Turkmenistan, Ukraine, United Kingdom, United Arab Emirates (UAE), Uzbekistan, Venezuela, Vietnam, Yemen, etc.