UNS S32760 Super Duplex Steel Socket Weld Swrf Flanges Manufacturer Stockist Exporter

- Home

- UNS S32760 Super Duplex Steel Socket Weld Swrf Flanges

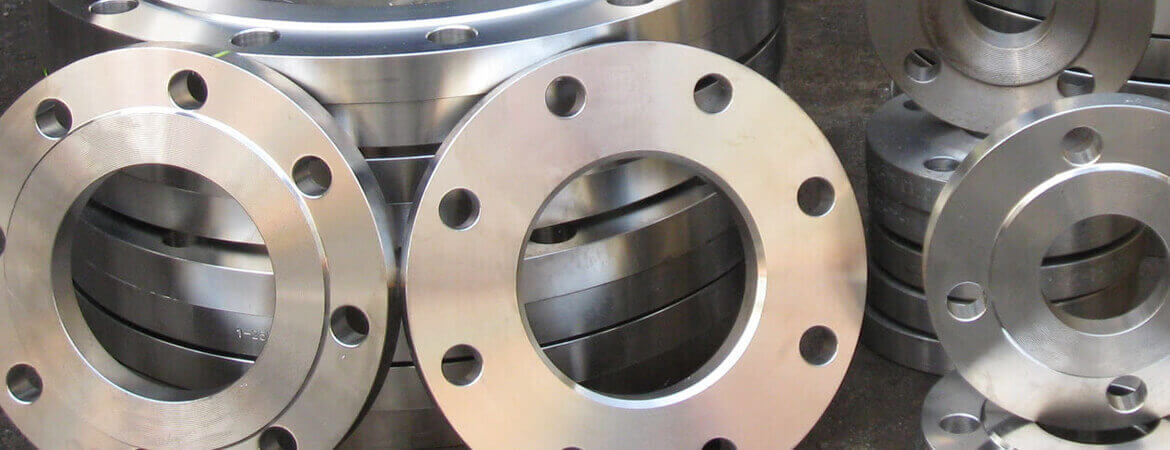

We are manufacturers, stockist and exporters of UNS S32760 Super Duplex Steel Socket Weld Swrf Flanges in Mumbai.

UNS S32760 (commonly known under trade names such as Zeron 100 or Super Duplex F55) is a premium super-duplex stainless steel alloy with a balanced austenitic/ferritic microstructure. Its high alloying content — typically 24–26 % chromium, ~6–8 % nickel, ~3–4 % molybdenum, copper, tungsten and nitrogen additions — gives it outstanding resistance to pitting, crevice corrosion, and stress corrosion cracking in chloride and harsh environments. The alloy also delivers elevated mechanical strength (yield, ultimate, fatigue) and superior toughness compared to conventional stainless steels.

As a Socket Weld Raised Face (SWRF) flange in S32760, this component offers compact, high-integrity joints especially in small bore piping systems. The socket weld design allows the pipe to be inserted into the flange bore and welded fillet-wise, providing a robust joint that is more compact than a butt weld. For systems where alignment, space constraints or ease of installation matter, S32760 SWRF flanges by a supplier like Synergy Engineering Solution form a compelling option. Through precise machining and quality control, the flange’s internal bore and face are made to tight tolerances to ensure fit and sealing integrity.

Synergy Engineering Solution acts as a manufacturer, stockist, and global exporter of these S32760 SWRF flanges. They maintain inventories of standard sizes and classes for prompt supply, while also offering custom fabrication for project-specific dimensions or specifications. Their export markets span the Middle East (Oman, Qatar, Saudi Arabia, UAE, Kuwait), Europe (Spain, Germany), North America (USA, Canada) and Africa. Their logistics and export infrastructure are adapted to handle high-grade alloy flanges — including sturdy export packing, documentation (Mill Test Certificates, inspection reports), compliance with import regulations, and coordination with freight forwarders.

In terms of performance, typical mechanical data for S32760 in the annealed condition includes a 0.2 % proof (yield) strength in the neighborhood of ~550 MPa, ultimate tensile strengths up to ~750–900 MPa, elongation ~25 %, Brinell hardness up to ~270 HB, and good impact toughness even at subzero temperatures. The alloy can maintain integrity in corrosive chloride media, with a Pitting Resistance Equivalent Number (PREn) ≥ 40, which underlines its suitability for seawater, saline, brackish, or aggressive chemical environments.

Types Of Flanges manufacturer

Applications for S32760 SWRF flanges are diverse. They find use in offshore and subsea piping tie-ins, seawater cooling systems, desalination circulation lines, chemical and petrochemical process piping, and in systems transporting acids, chlorides or sour gases. Designers often prefer them where weight savings and thinner wall sections are beneficial but corrosion performance must not be compromised. A supplier like Synergy would support customers with engineering guidance, verifying welding procedures, flange-to-pipe compatibility, and recommending companion fasteners and gasketing to match the high-performance alloy.

By leveraging advanced manufacturing processes, strict quality assurance, and a robust global supply network, Synergy Engineering Solution & Exporter continues to be a preferred source for UNS S32760 Super Duplex Steel WNRF Flanges worldwide. Whether it’s for marine, offshore, chemical, or power generation applications, these flanges guarantee excellent strength, superior corrosion protection, and long service life — making them an essential component in any critical piping system.

UNS S32760 Super Duplex Steel Socket Weld Swrf Flanges

Specification (Summary)

| Property | Details |

|---|---|

| Material | UNS S32760 — Super Duplex Stainless Steel (commonly referenced as F55) |

| Flange Type | Socket Weld Raised Face (SWRF) |

| Standards | ASTM A182 / ASME SA182, ASME B16.5 (flange dimensions), EN 1092-1 as applicable |

| Size Range | ½" to 48" (standard) — custom sizes available |

| Pressure Classes | 150#, 300#, 600#, 900#, 1500#, 2500# |

| Face Types | Raised Face (RF), Flat Face (FF), RTJ (on request) |

| Heat Treatment | Solution annealed and rapidly cooled (water quenched) to obtain duplex microstructure |

| Documentation | MTC (EN 10204 3.1 / 3.2), PMI, NDT / 3rd-party inspection on request |

Chemical Composition (Typical ranges, wt. % — verify with MTC)

| Element | Typical Range (wt. %) |

|---|---|

| Carbon (C) | ≤ 0.03 |

| Chromium (Cr) | 24.0 – 26.0 |

| Nickel (Ni) | 6.0 – 8.0 |

| Molybdenum (Mo) | 3.0 – 4.5 |

| Nitrogen (N) | 0.24 – 0.32 |

| Manganese (Mn) | ≤ 2.0 |

| Silicon (Si) | ≤ 1.0 |

| Copper (Cu) | 0.3 – 1.0 |

| Tungsten (W) | 0.2 – 0.9 |

| Iron (Fe) | Balance |

Note: Composition ranges above are typical commercial ranges. Always confirm exact chemical composition from the supplier's Mill Test Certificate (MTC) for each heat.

Mechanical Properties (Typical, solution-annealed condition)

| Property | Typical Value |

|---|---|

| Ultimate Tensile Strength (UTS) | ~750 – 900 MPa |

| Yield Strength (0.2% proof) | ~550 – 720 MPa |

| Elongation (A) | ≥ 15 – 25% |

| Hardness (Brinell) | Typically ≤ 290 – 310 HB (depends on product form) |

| PREn (Pitting Resistance Equivalent) | ≥ 40 (typical) |

| Service Temperature | Suitable from cryogenic service to ≈300°C; consult supplier for high-temperature limits |

Equivalent Grades / Cross References

| Designation | Equivalent / Note |

|---|---|

| UNS | S32760 |

| ASTM / ASME | F55 (often referenced for wrought forms under A182 etc.) |

| Trade Names | Zeron 100 (and other vendor trade names) |

| EN / DIN | No single universal 1:1 EN number; cross-references vary by supplier — confirm with MTC / vendor |

Frequently Asked Questions (FAQ)

Q: Where are S32760 SWRF flanges typically used?

A: In seawater systems, desalination plants, offshore platforms, chemical processing, oil & gas facilities and wherever chloride/pitting resistance plus high strength are required — especially in small-bore or space-restricted piping where socket weld joints are preferred.

Q: Can Synergy provide MTC and third-party inspection?

A: Yes — standard supply includes Mill Test Certificates (EN 10204 3.1/3.2 if requested). Synergy can arrange PMI reports, NDT and third-party inspection per project requirements.

Q: Are these flanges NACE/ISO 15156 compliant for sour service?

A: S32760 is commonly used in sour and chloride environments; Synergy can supply material meeting NACE MR0175 / ISO 15156 requirements where applicable and documented.

Q: What information should I include in an RFQ?

A: Provide quantity, nominal size & rating (e.g., 1" CL600), flange standard (ASME B16.5 / EN1092-1), any special machining or face finish, required certificate level (3.1 / 3.2), and delivery destination — this enables a complete, export-ready quotation.

In order to alter the physical and mechanical characteristics of metal without altering its original shape and size, we offer a variety of heat treatment services, including hydrogen heat treatment, HIC testing, blasting and painting, cutting, arc welding, epoxy cutting, PMI testing, hydro testing, NACE testing, and SSC testing. Although heat treatment is frequently linked to a metal's increased strength, it can also be used to change specific manufacturability goals, such enhancing machinability, formability, ductility, etc. The metal and heavy manufacturing sectors use our services. Customers have expressed great pleasure with our services' precision, efficacy, cost, and prompt delivery.

Flanges Testing Methods

Flanges Applications

We supply Pipes Worldwide.

Exporting Steel Pipes & Tubes to over 60 countries including Afghanistan, Albania, Andorra, Angloa, Austria, Australia, Bahrain, Bangladesh, Bhutan, Brazil, Brunei, Belarus, Belgium, Bulgaria, Cambodia, China, Cyprus, Croatia, Czech Republic, Canada, Denmark, Estonia, Egypt, Finland, France, Germany, Greece, Georgia, Hungary, Iceland, Ireland, Italy, Indonesia, Iran, Iraq, Israel, Japan, Jordan, Kazakhstan, Kuwait, Kyrgyzstan, Lebanon, Latvia, Latin America, Liechtenstein, Lithuania, Luxembourg, Malta, Madagascar, Mexico, Moldova, Monaco, Malaysia, Maldives, Mongolia, Myanmar (Burma), Nepal, New Zealand, North Korea, Netherlands, Norway, Nigeria, Oman, Poland, Portugal, Pakistan, Palestine, Philippines, Qatar, Russia, Romania, Russia, San Marino, Serbia and Montenegro, Slovakia, Slovenia, Spain, Sweden, Switzerland, Saudi Arabia, Singapore, South Korea, South Africa, Sri Lanka, Sudan, Syria, Taiwan, Tanzania, Tajikistan, Thailand, Turkey, Turkmenistan, Ukraine, United Kingdom, United Arab Emirates (UAE), Uzbekistan, Venezuela, Vietnam, Yemen, etc.